MindCUT V5.3 release offers the following new features and enhancements:

PATTERN MATCHING

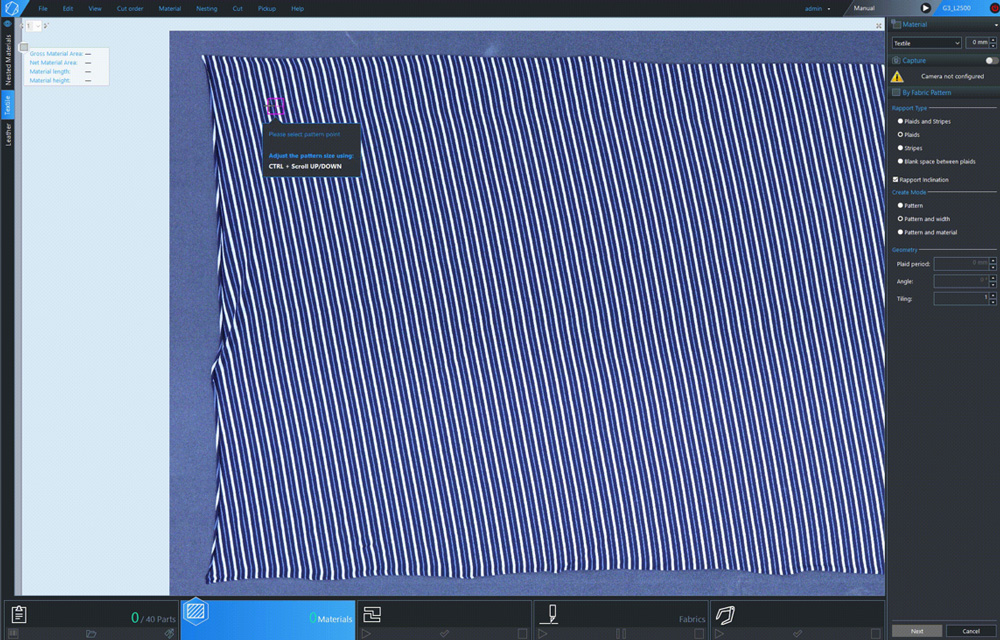

Guidance for material creation

Tooltips showing the steps to create a material with pattern. A measurement tool is included in the tooltip.

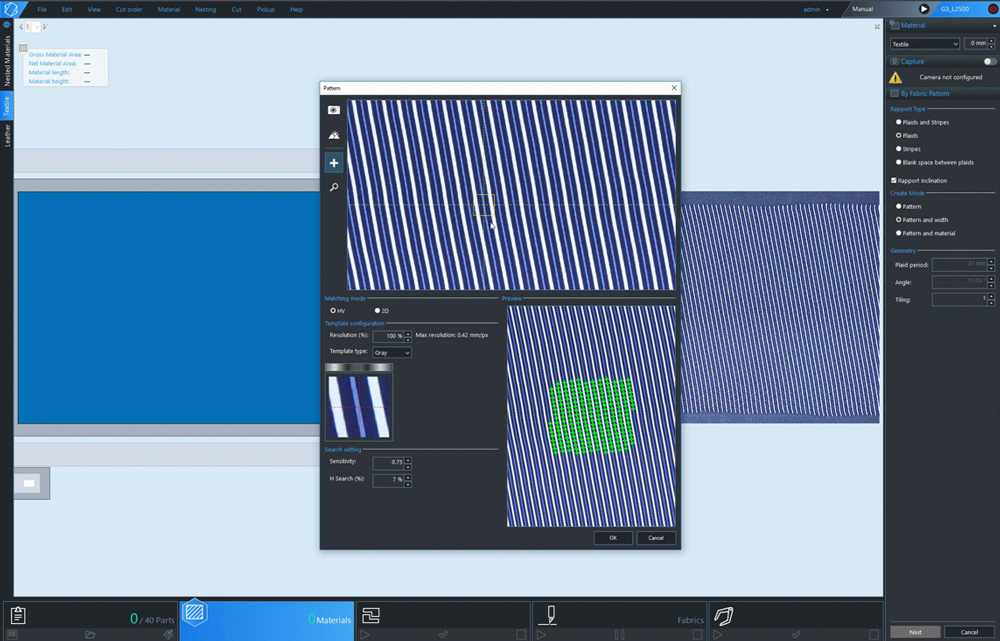

Guidance and preview for pattern recognition

Inspection area to preview the effectiveness of settings to find the selected pattern in the fabric around the inspection point.

User-oriented workflows

Streamline process when creating a material based on the information saved in PDM.

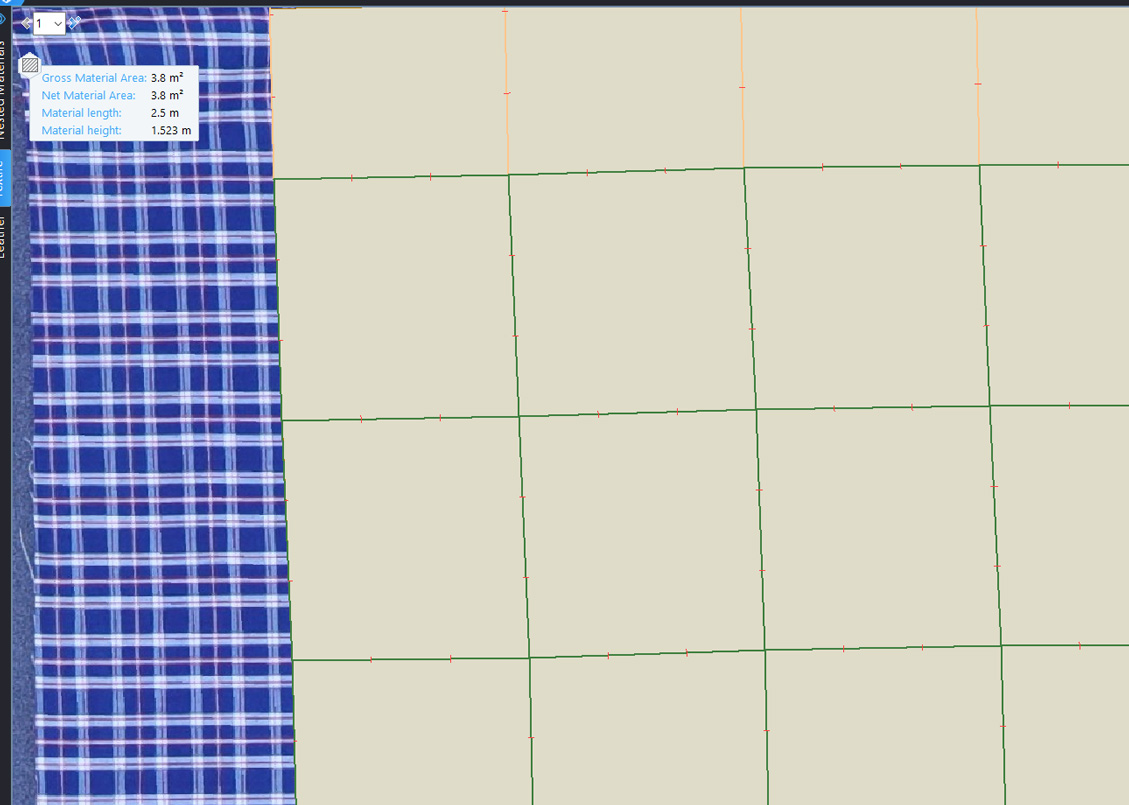

New tilling capabilities

Move the grid according to each atomic pattern. Recommendation to use tilling in patterns with less than 20 mm.

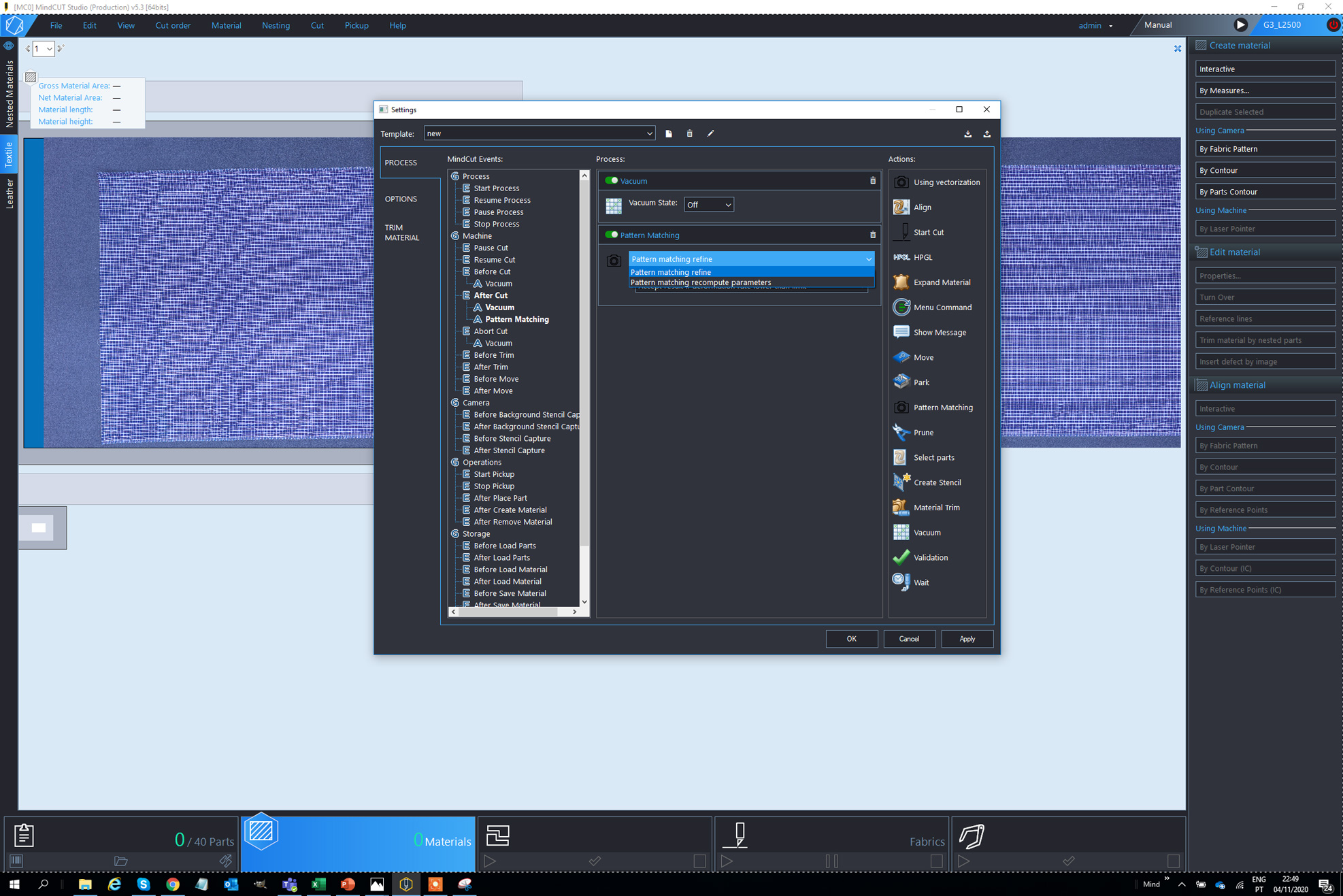

New process related functions

Added to recompute parameters function to the process.

NEW HARDWARE SUPPORTED

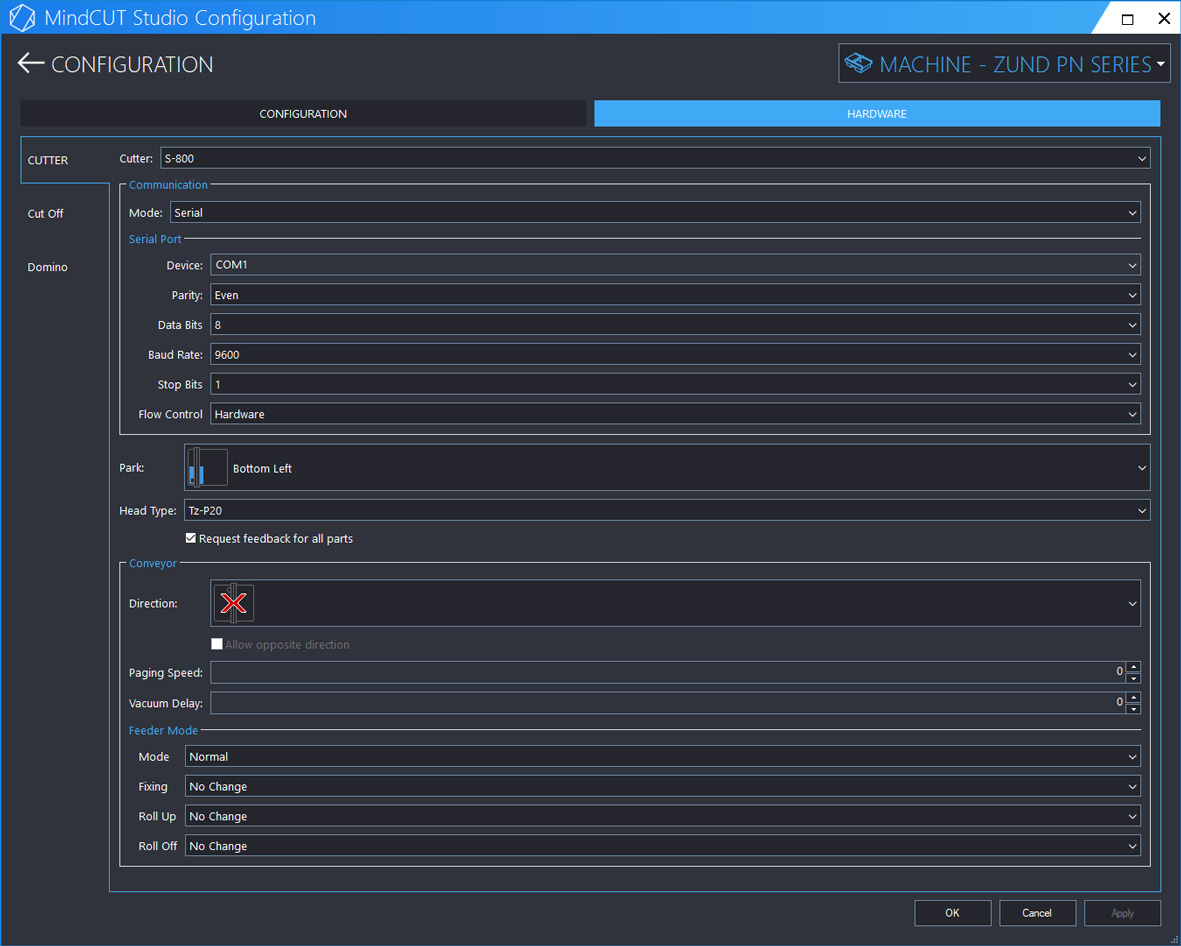

PN machines support

new PN controller

Cradle feeder 2 with cut-off unit

Support for new cradle feeder with integrated cut-off unit

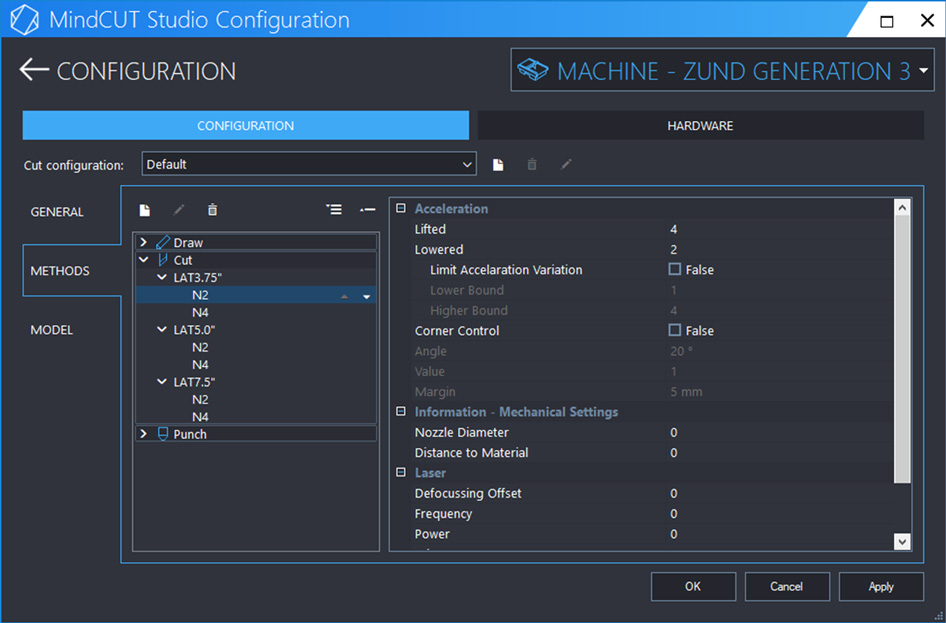

Laser module support

New module and new tools available in Cut template

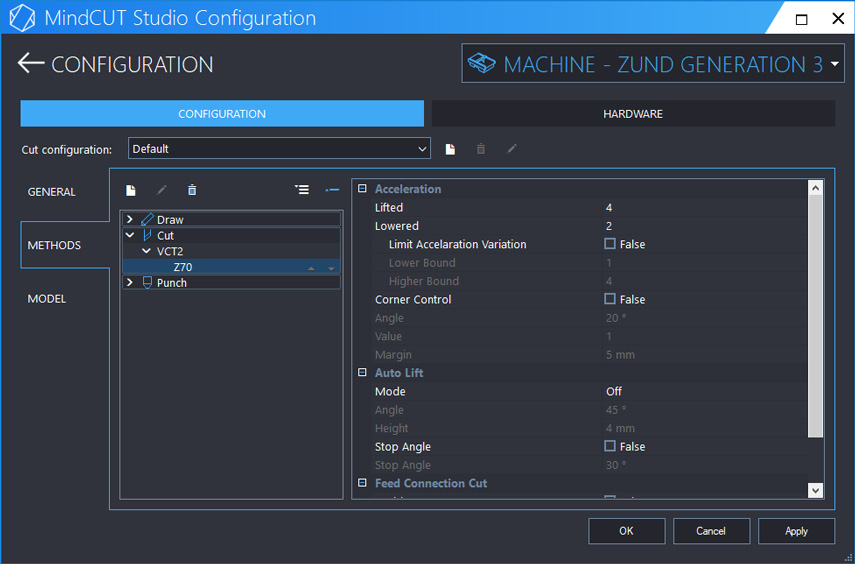

New VCT2 tool support

New tool available in Cut Template

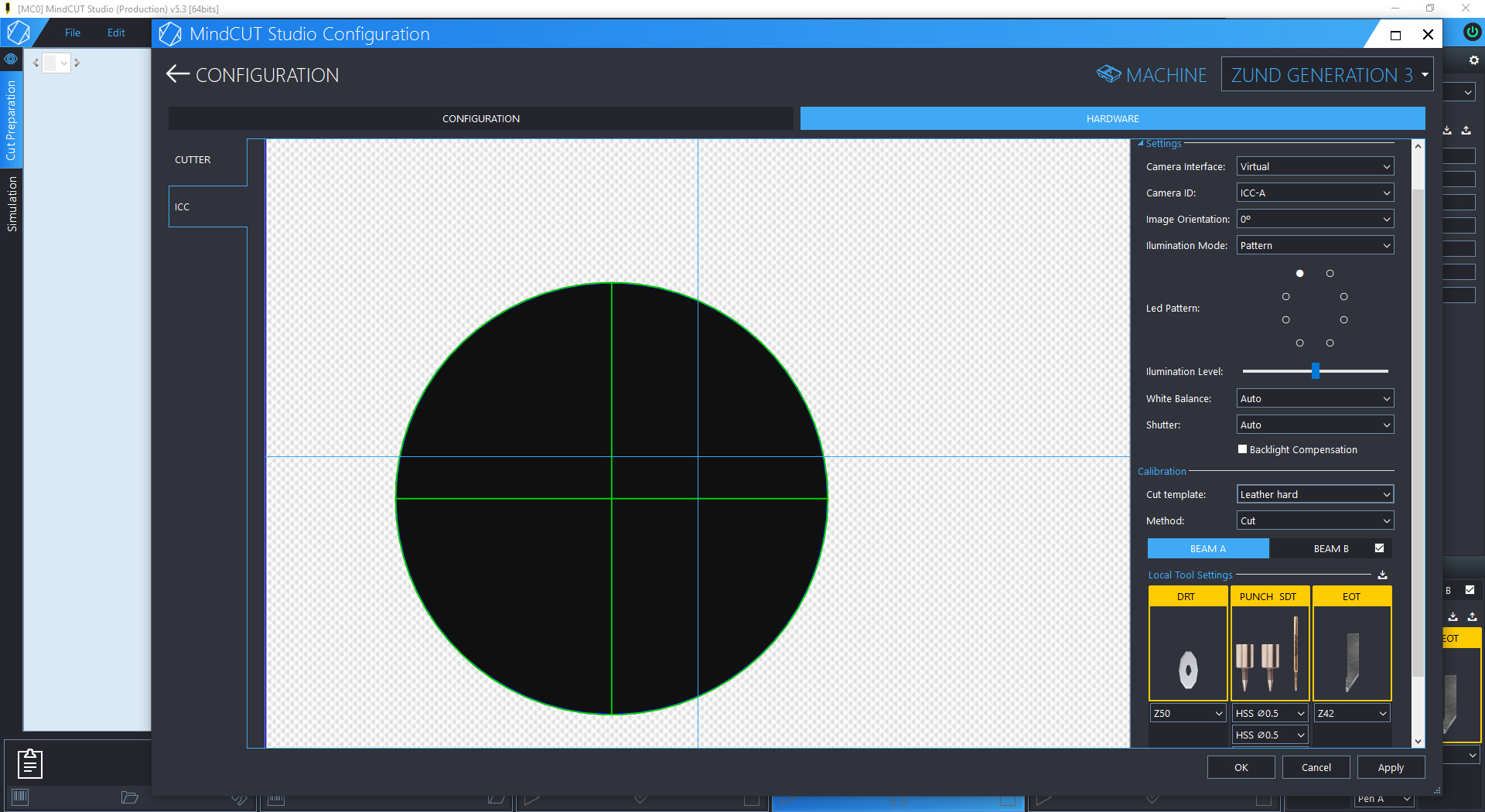

Enhanced ICC calibration process

More user-friendly ICC calibration, with new tips and new controls (e.g., mouse wheel to increase/decrease circle size)

New hotkeys for pickup

Support for remote interface - push buttons - for pickup process control.

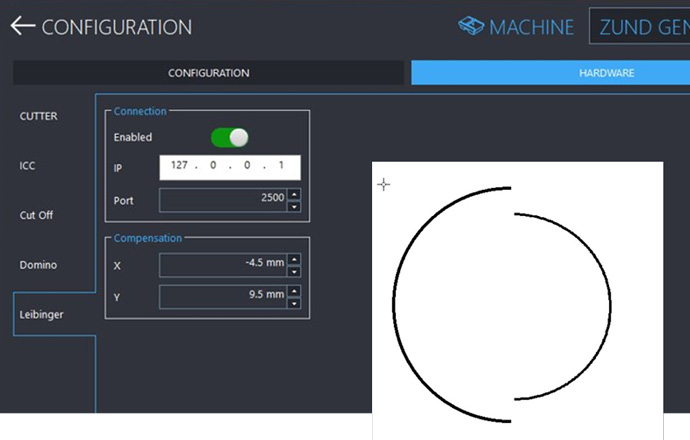

Support for Leibinger Inkjet

New device configuration available.

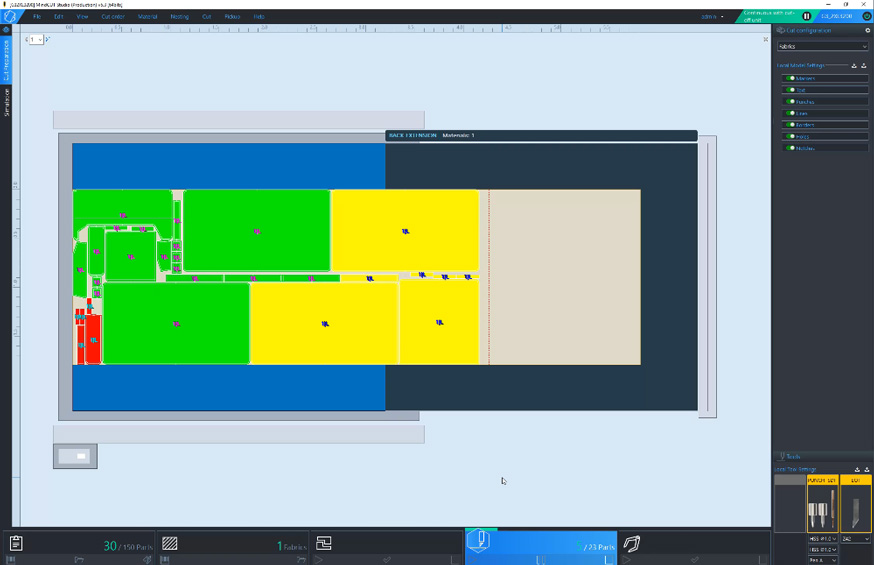

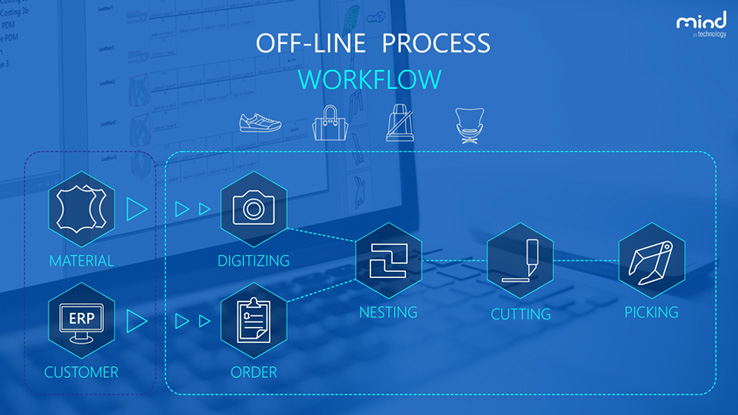

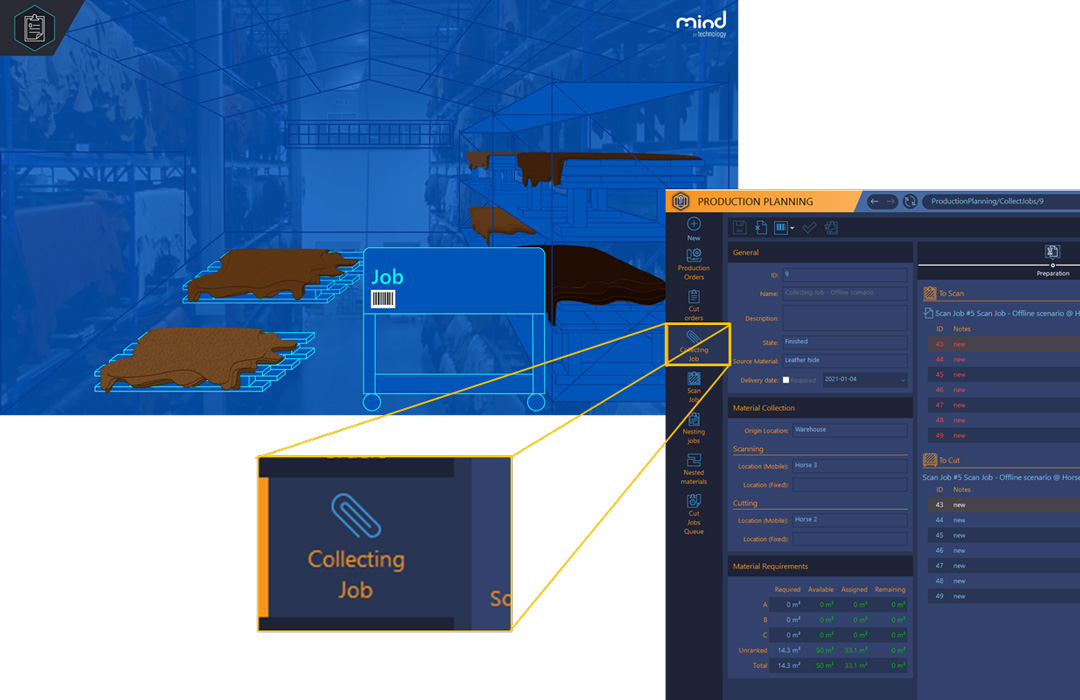

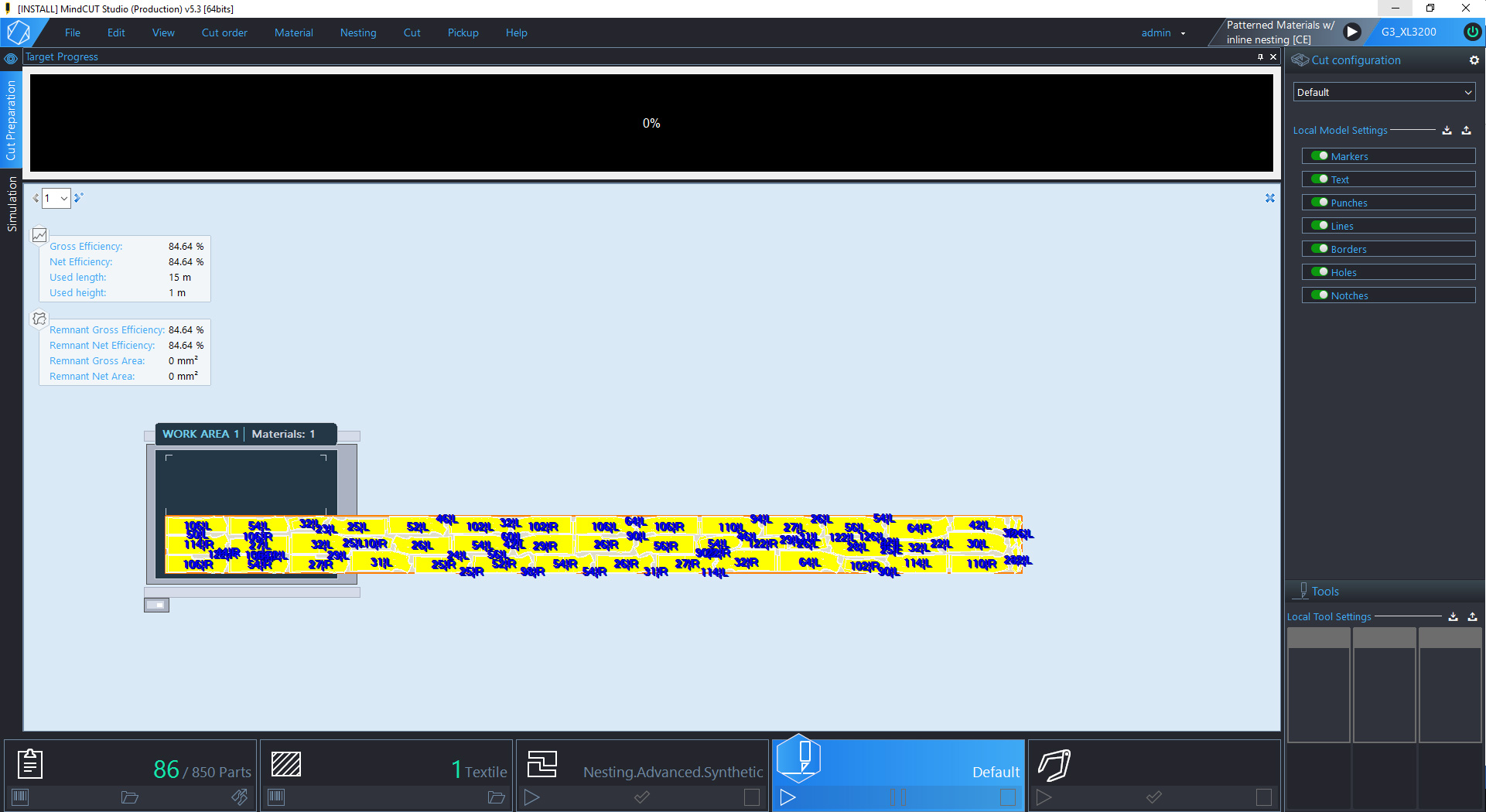

OFFLINE PROCESS

Enhanced scan-to-stock process support

1. Digitize incoming hides

2. Collect the previously scanned hides according to Order needs

3. Perform the nesting offline over the collected hides

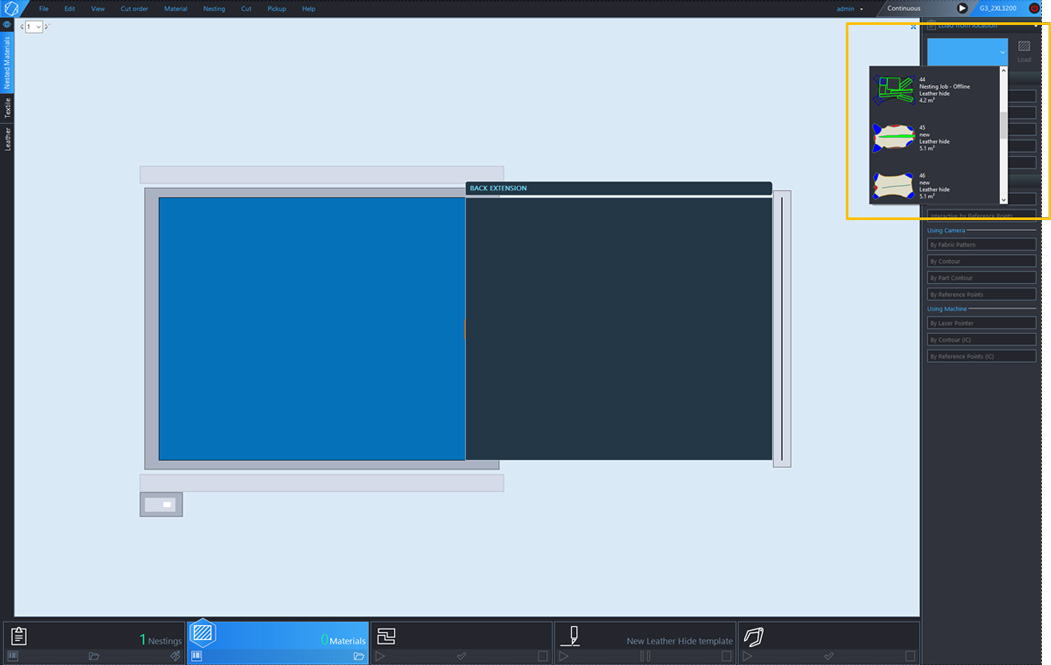

4. Preview the hides of a certain location and load one by one to cut

Support scan-to-job process

1. Collect unscanned hides from stock according to Order needs

2. Digitize the hides assigned to the scan job

3. Perform the nesting offline over the collected hides

4. Preview the hides of a certain location and load one by one to cut

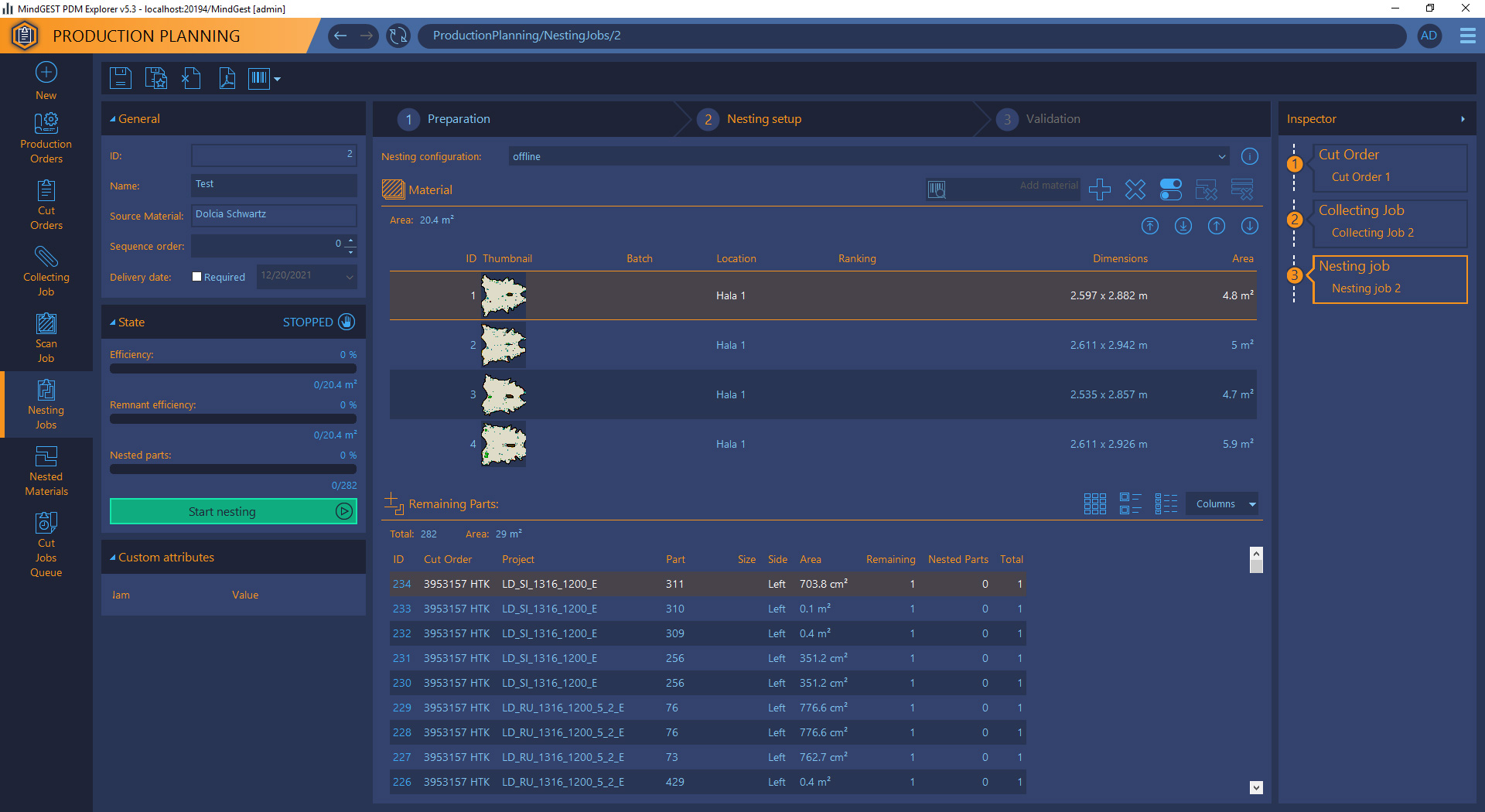

Improved Nesting Job interface

Preparation with inputs coming directly from a Cut Order or from a previously created Collecting Job, with the possibility to reorganize the materials sequence.

Validation of nested materials with a preview of the remaining parts that were not placed

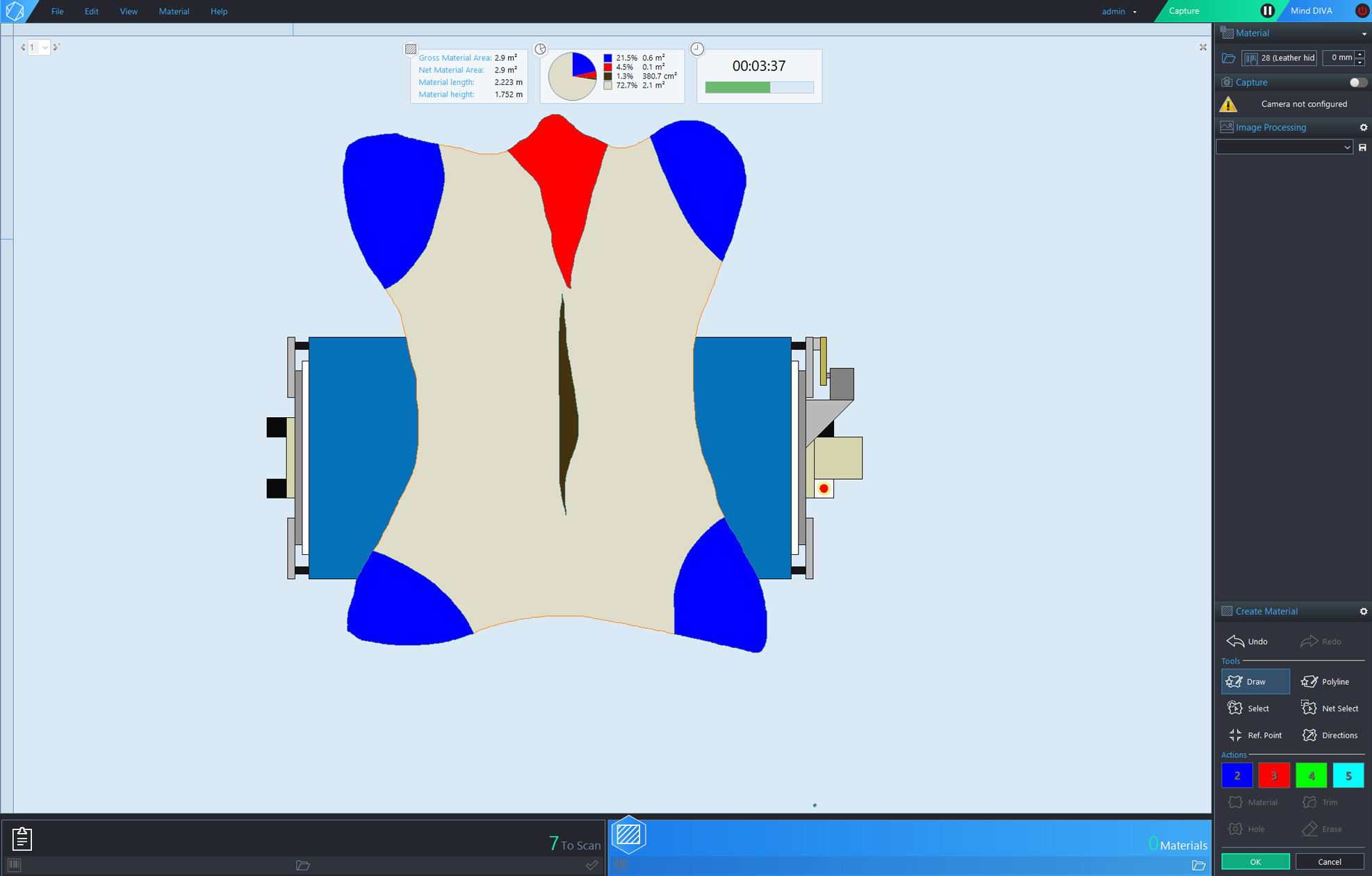

Improved MindCUT DIVA interface

New interfaces for creation or loading of a Scan Job and scanning of the hide with time target.

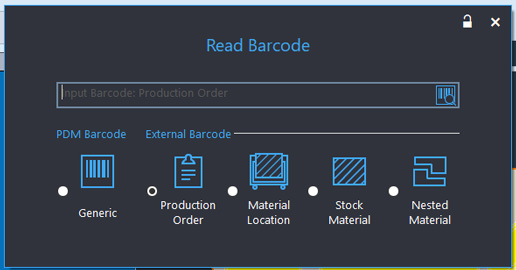

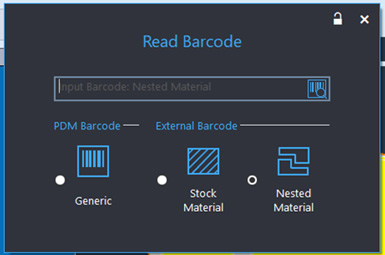

Expanded scannable elements in MindCUT

Load from barcode (either from PDM or an external reference) into the preparation Tab – for Production Orders, Material Locations, Stock Materials and Nested Materials/Markers.

Load from barcode (either from PDM or an external reference) into the workspace – for Stock Materials and Nested Materials/Markers.

Enhanced use of materials from a defined location

Overview of every material available in a loaded location.

Possibility to load a material from a location, either via barcode or using the dropdown list on the right-hand side.

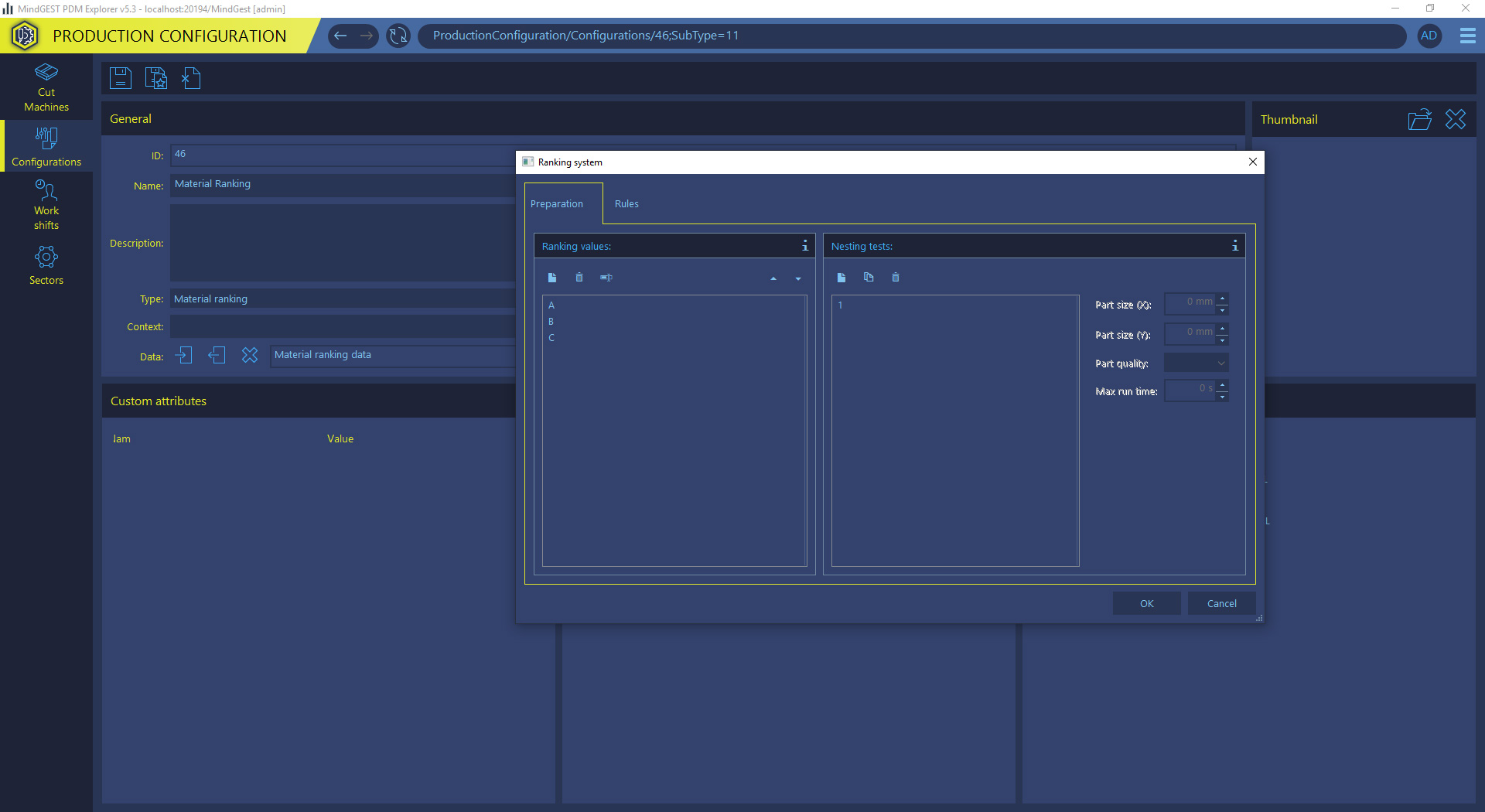

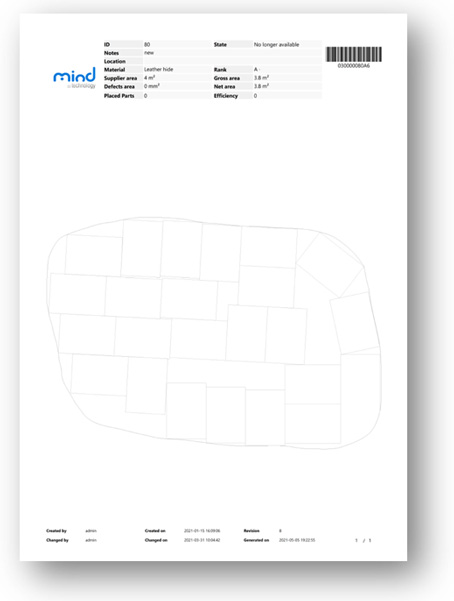

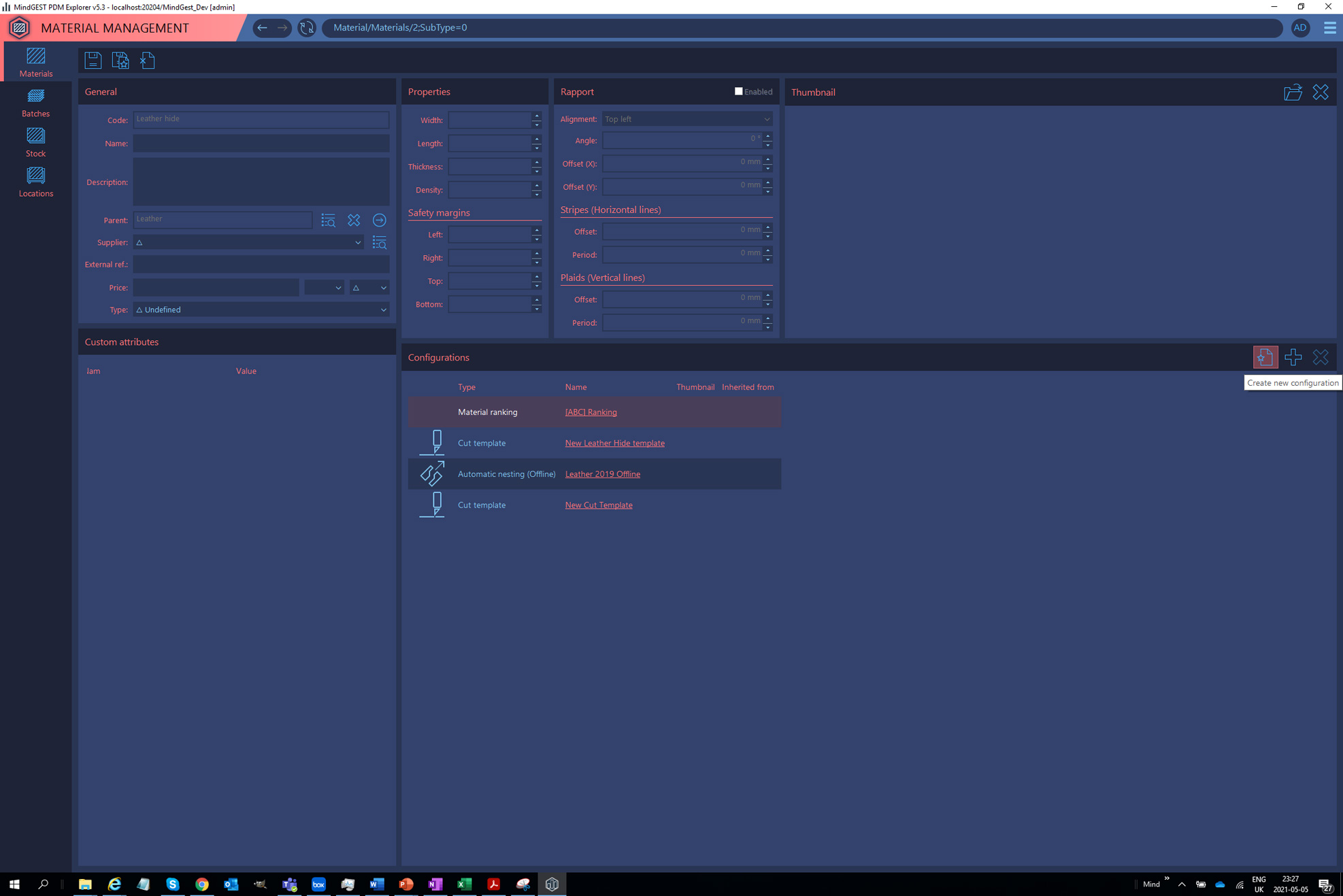

New generic ranking system [Supplier & Production]

Configurable ranking system to be used wither for supplier evaluation of for production stock balance.

PRINTED CUT

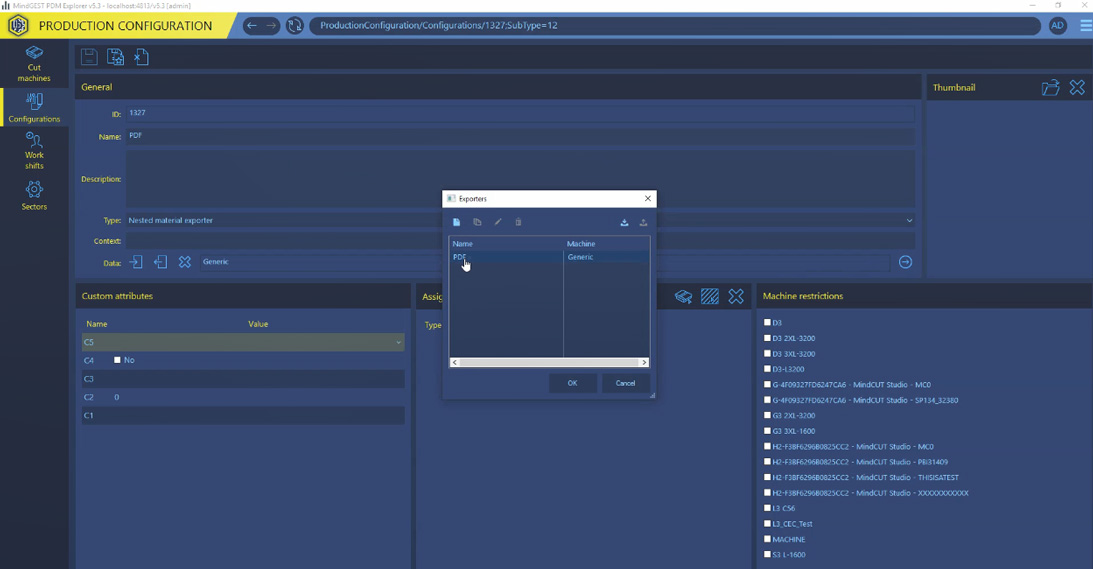

Export nestings automatically via Data Integration Center

Create a configuration of “Nested material exporter”. Create an automatic export task in Data Integration Center.

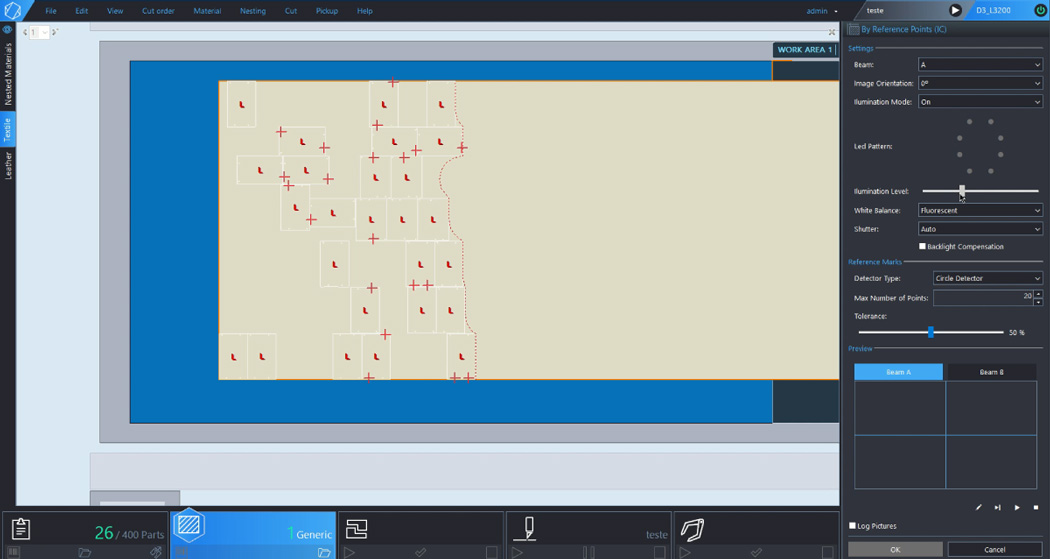

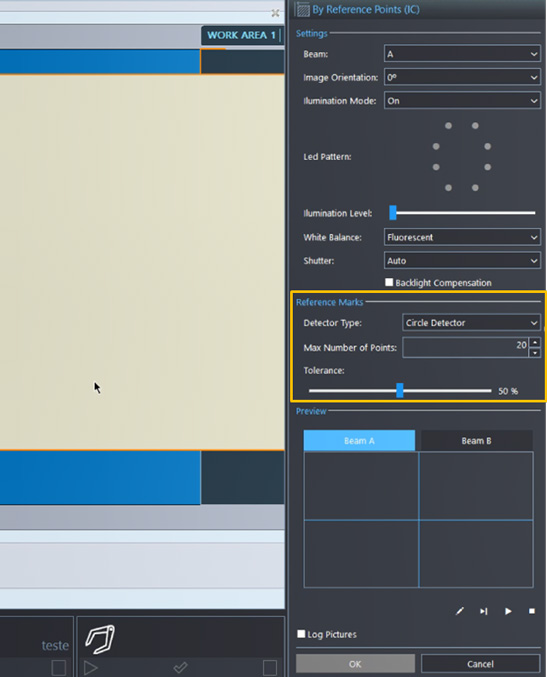

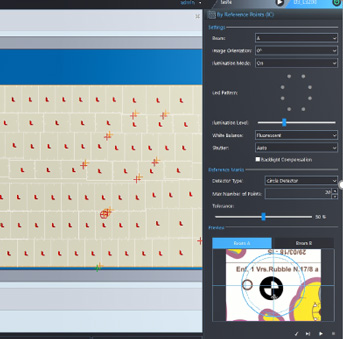

Enhanced ICC capture parameters

Control ICC capture parameters while in the Align by Reference Points tool.

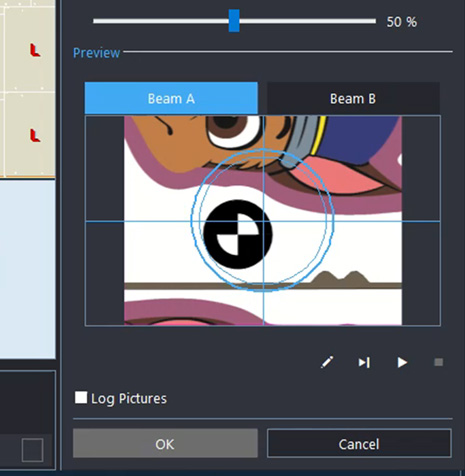

Reference point circularity tolerance adjustment

Interactive adjustment of a reference point diameter’s tolerance

Interactive registration of a point using the ICC picture

The interactively defined point will be the image center.

Improved ICC control

The ICC control was enhanced, delivering now a more fluid movement while in manual beam control mode.

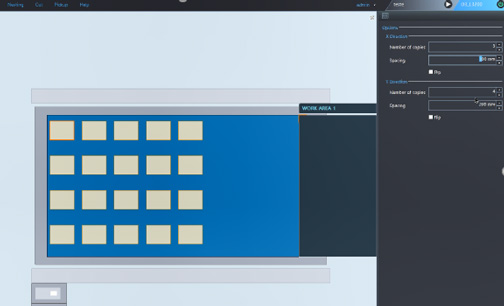

Material creation

Possibility to add multiple copies in a row based at a certain distance to the other material.

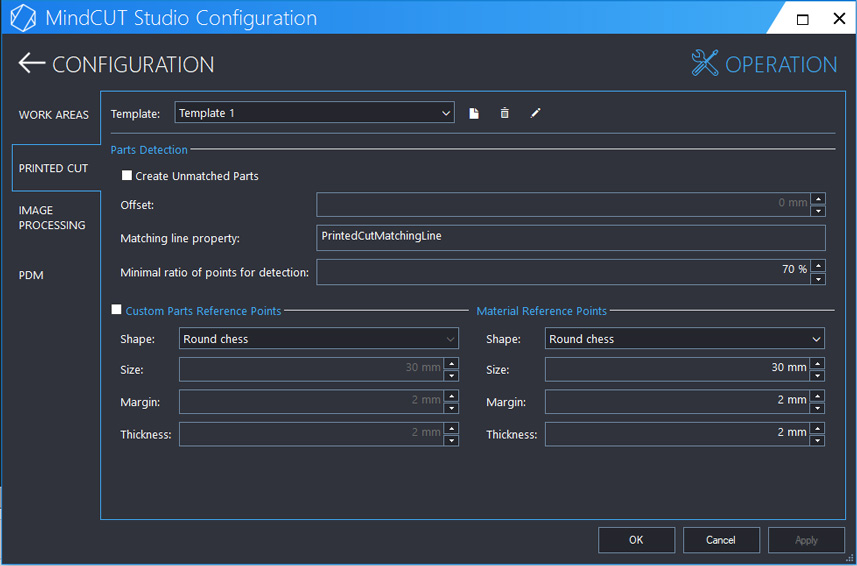

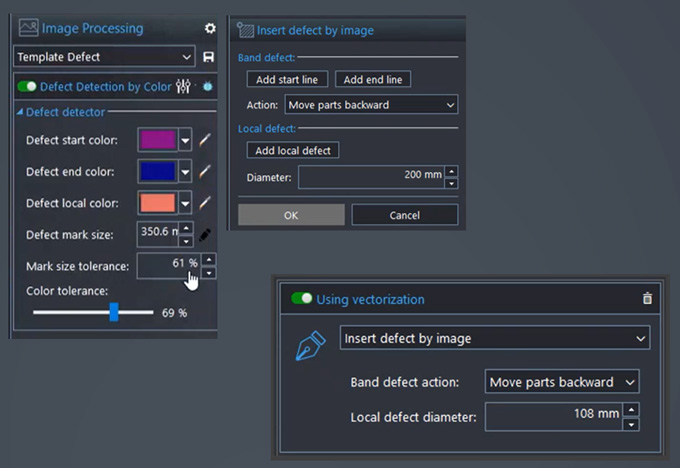

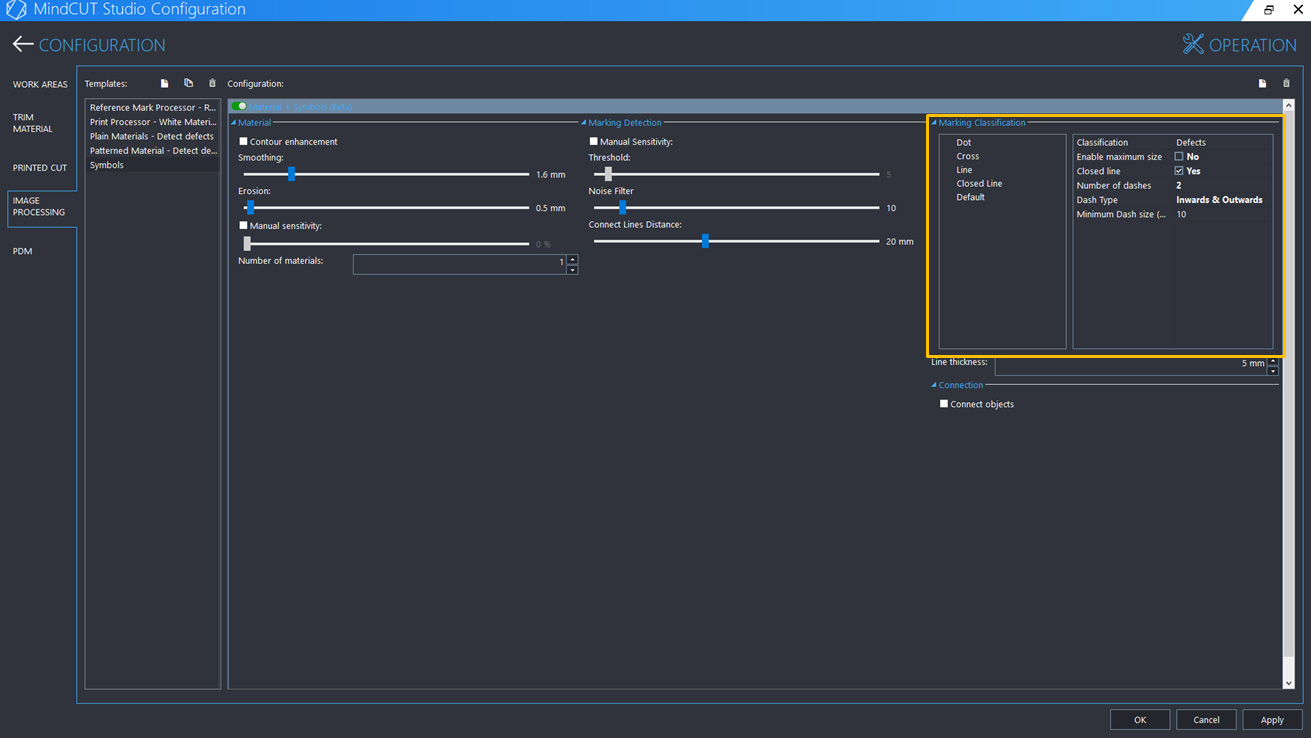

Enhanced printed cut parts detection setup

Add % of allowed undetected points to Printed Cut template.

Enhanced Print Image Processing Engine setup

Expose smoothing parameter for Print Image Processing Engine.

MISCELLANEOUS

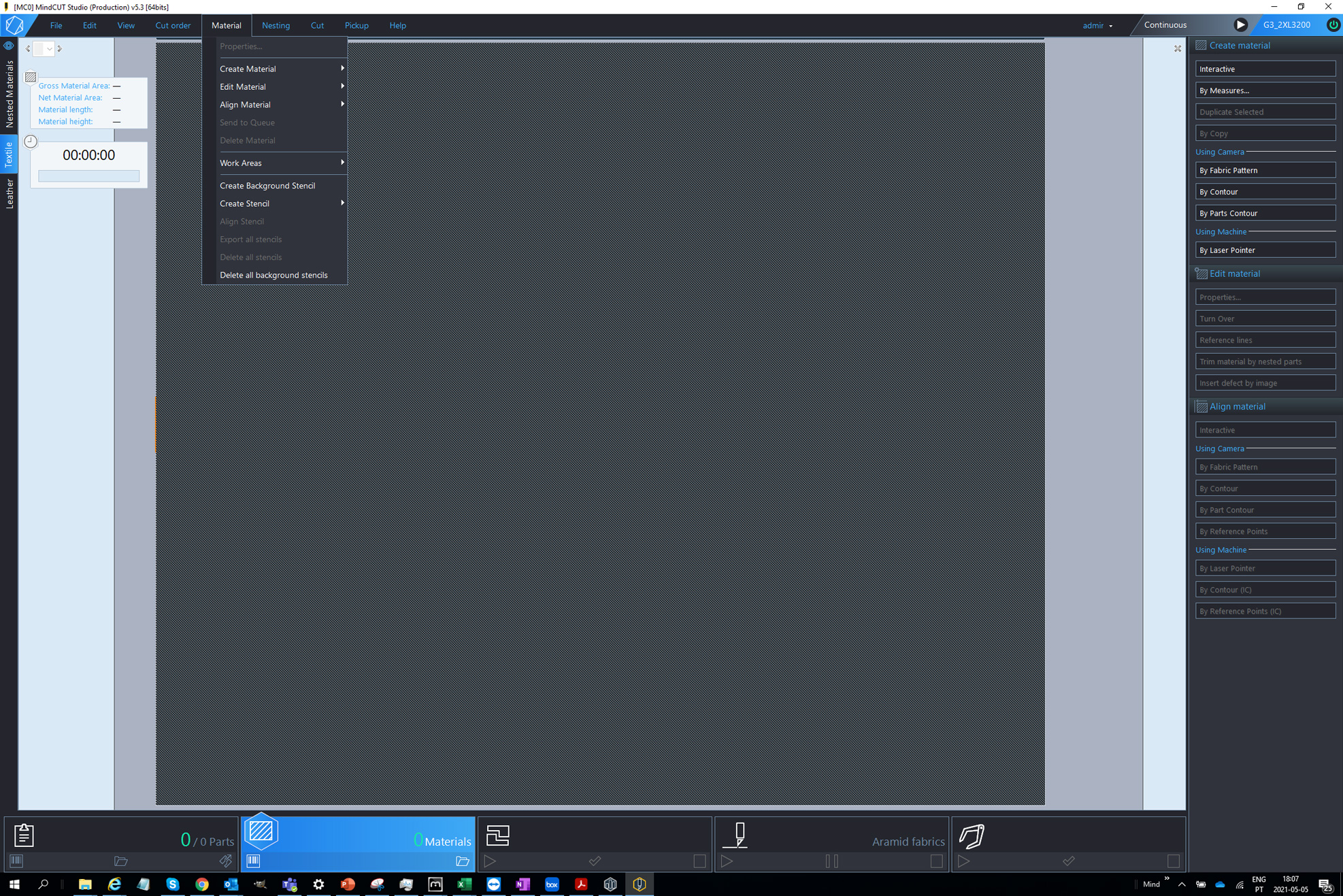

Possibility to delete background stencils

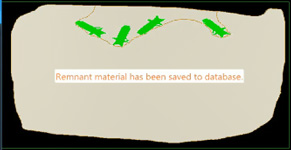

Remnant generation notification on pickup screen

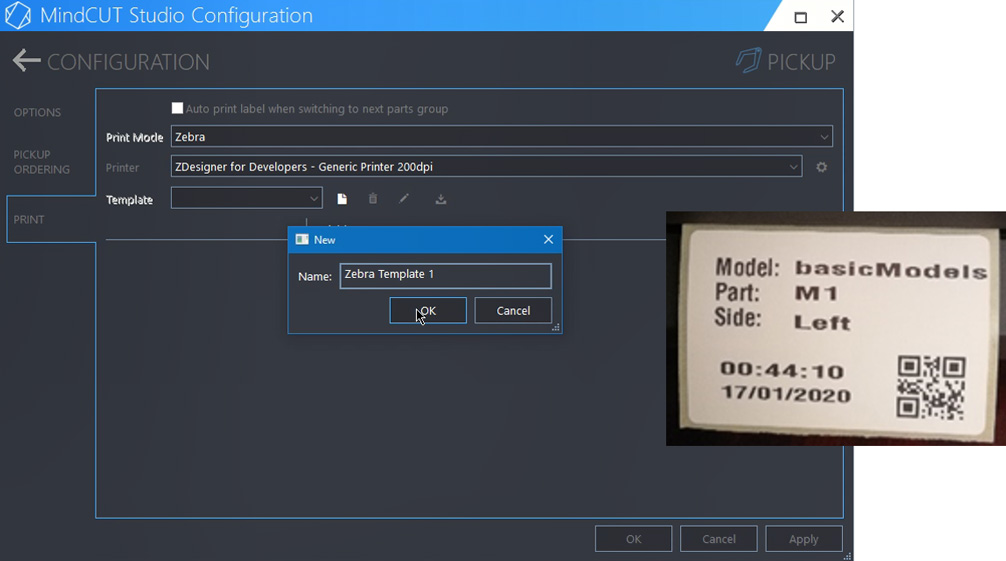

Custom labels for pickup

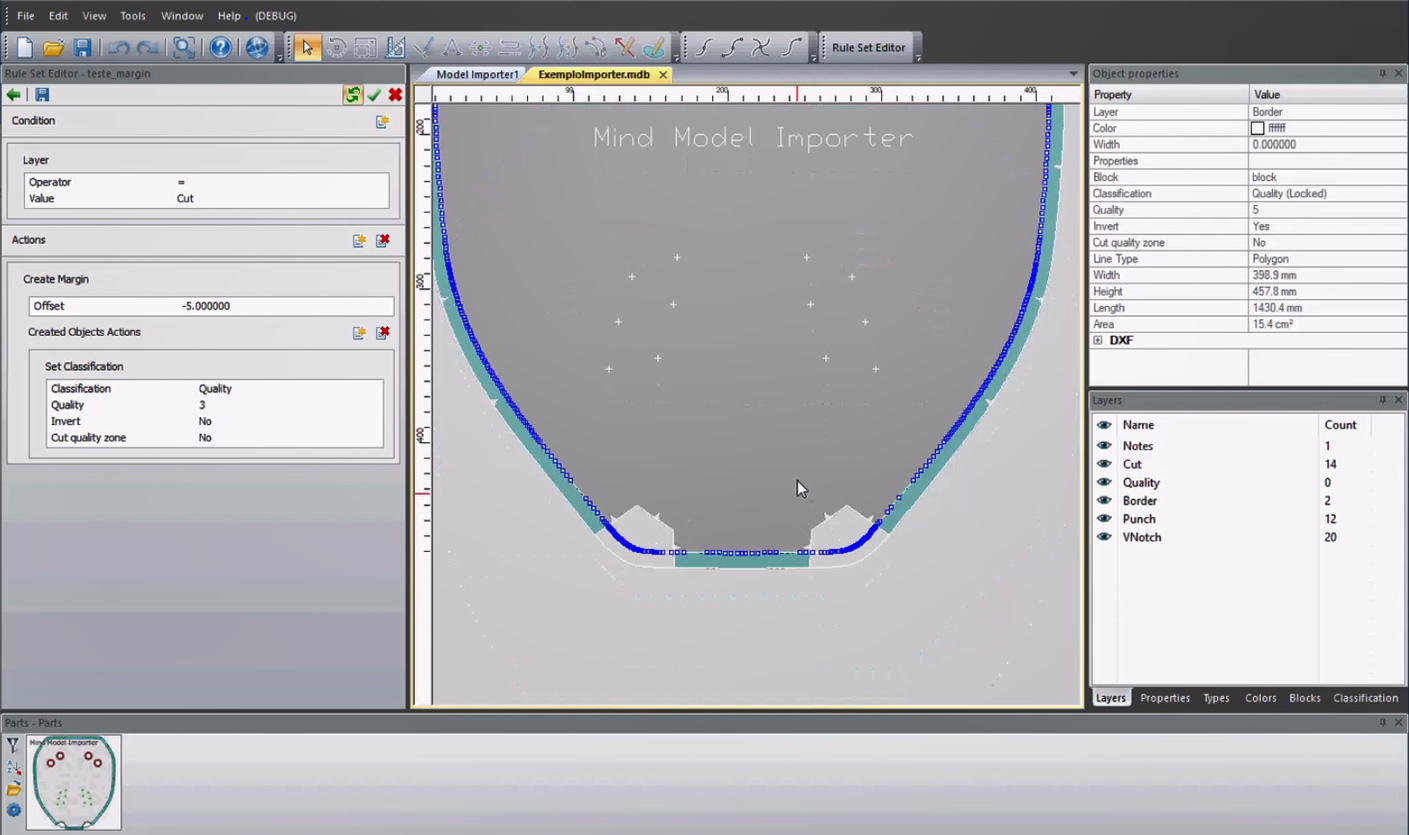

Automatic sewing margin by ruleset action

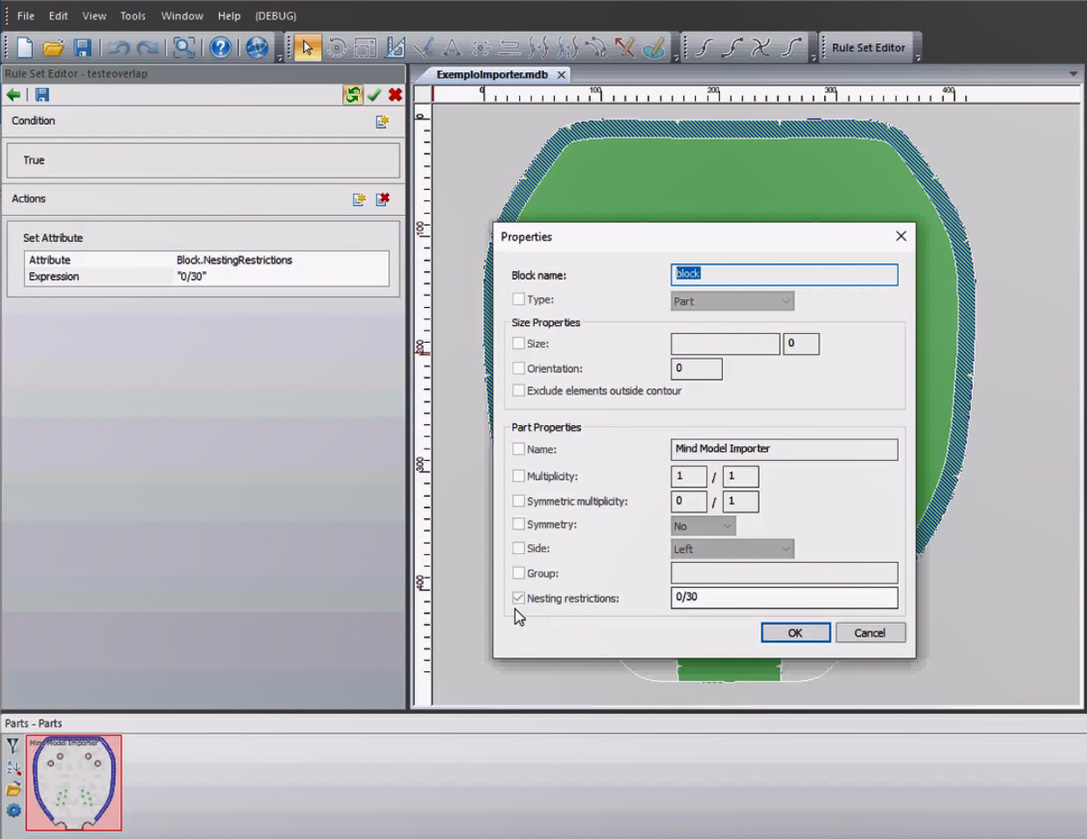

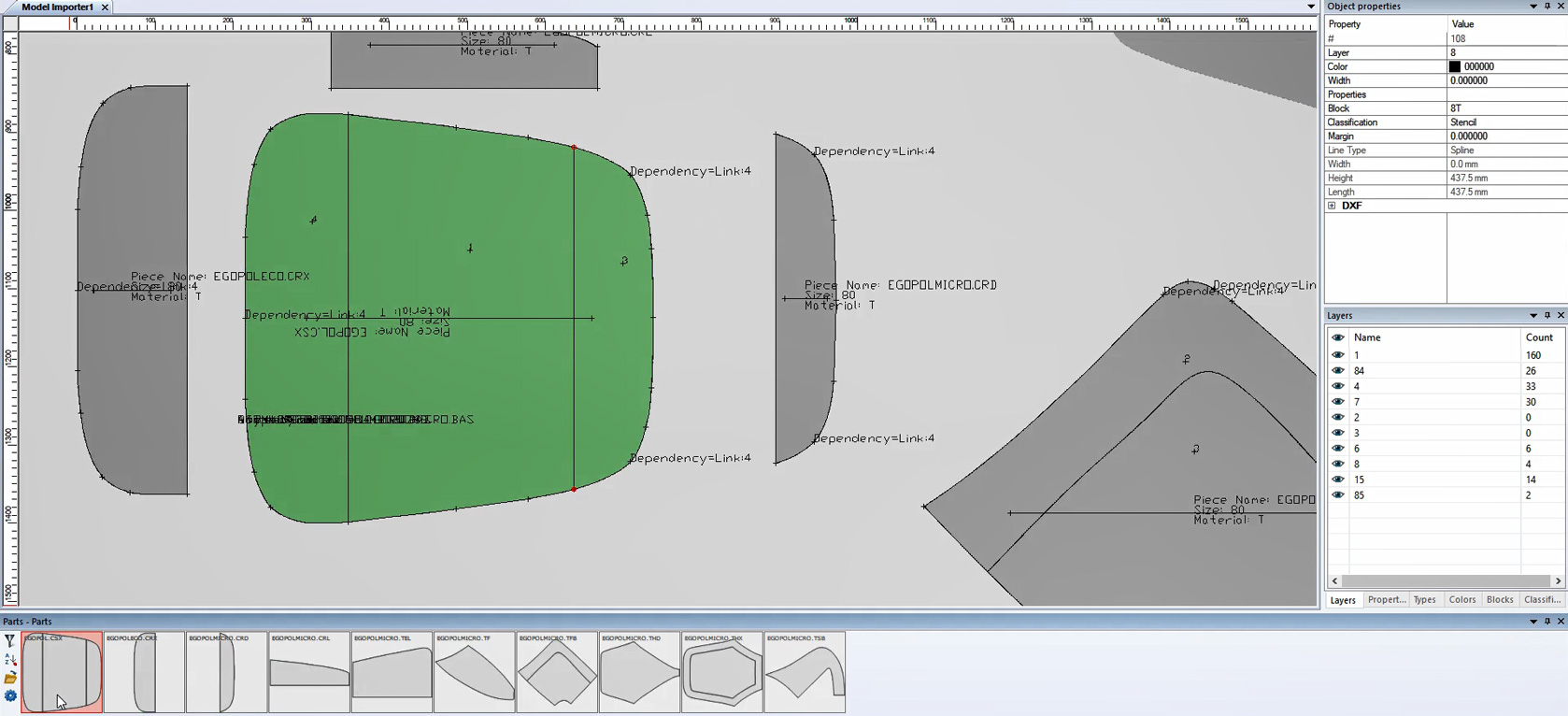

Assign nesting restriction in Model Importer (as MindCUT)

Defects can be marked with only one label

Support for roll consumption accounting within Cut Operations

Material Stock item report including ranking information

Enhanced PDM Explorer dashboard

Including now status for all connected services on PDM Explorer dashboard.

Enhanced material management template

Quicker creation of template placeholders and link to a specific material.

AAMA standard layer 8

Layer 8 from AAMA standard represented as guidelines, but not cut.

Base quality assignment

Assign base quality based on percentage of qualities to be a metadata instead of external contour.

Generic metadata support

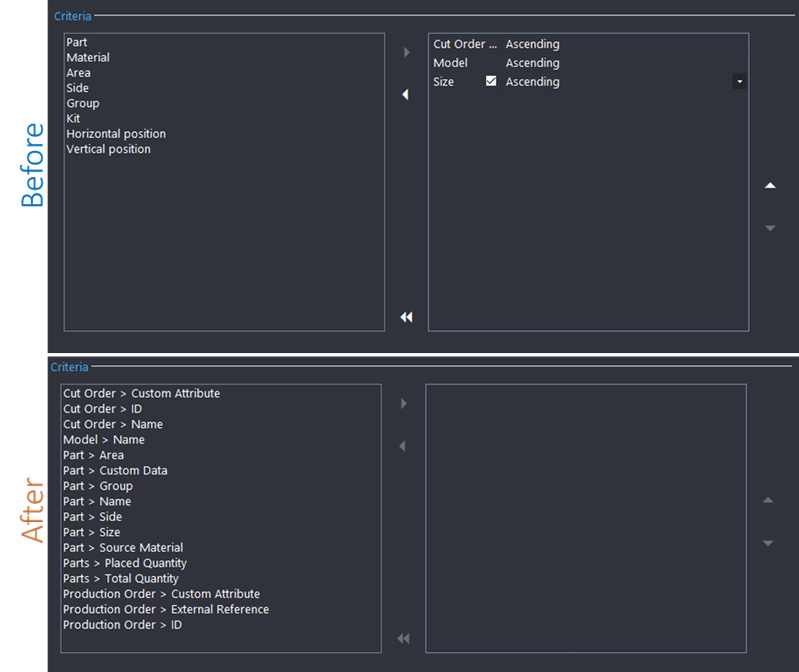

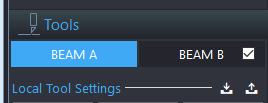

Support for generic metadata to be used on MindCUT for several purposes. A new set of parameters is available for pickup and nesting ordering, including Model and PDM related Custom Attributes. Available for Interactive Nesting, Automatic Nesting, Pickup ordering, and Pickup label info.

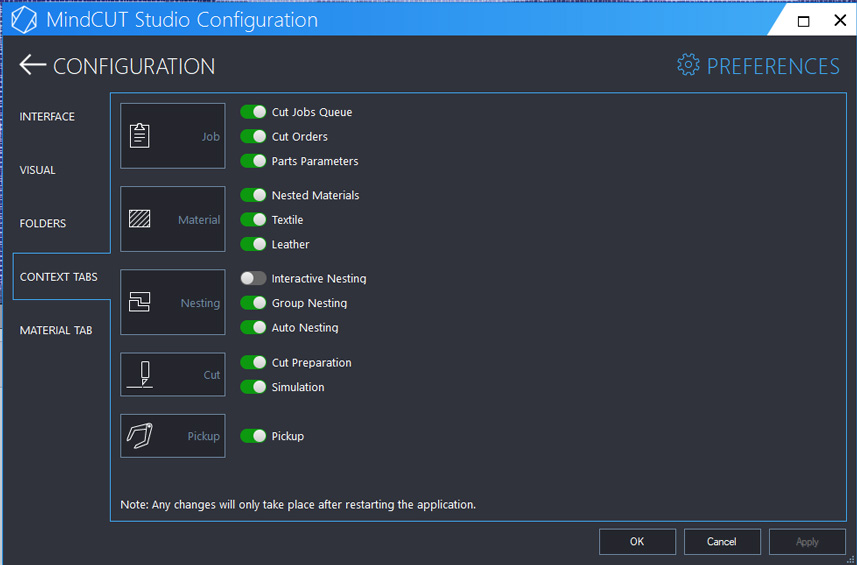

Enhanced configuration context tabs

Hide and show the left-hand side sub-contexts according to customers’ needs. Hiding every sub-context from a context will also hide the context tab from the interface.

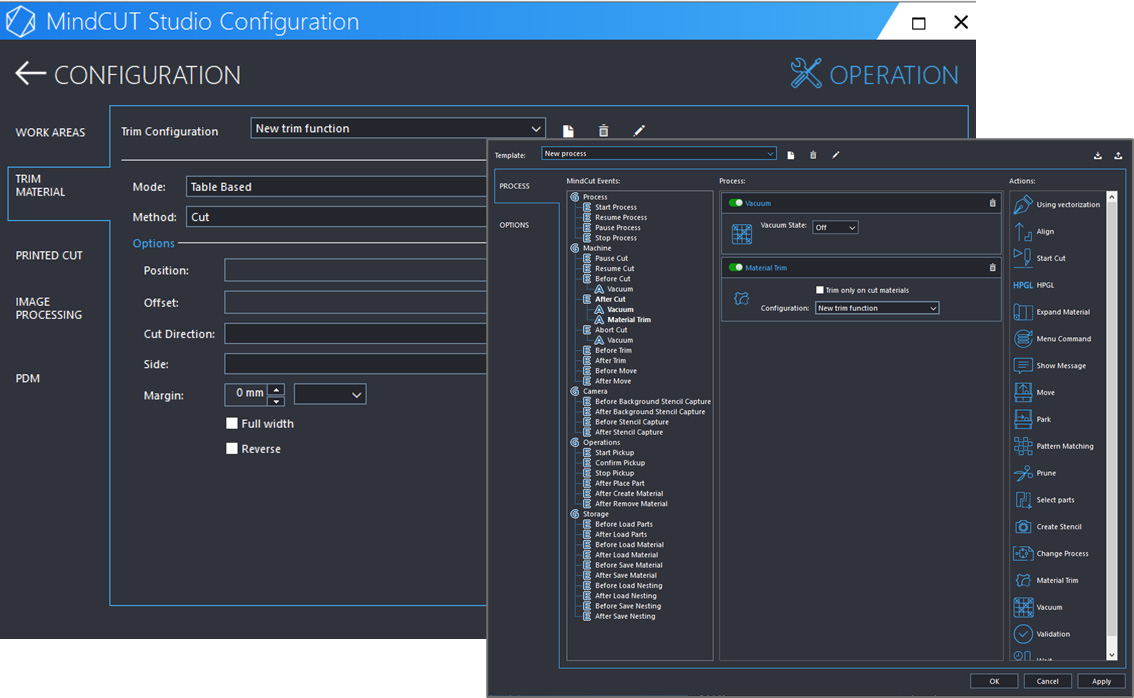

Multiple trim templates

Configurable trim templates to be used differently in the process, according to the workflow needs.

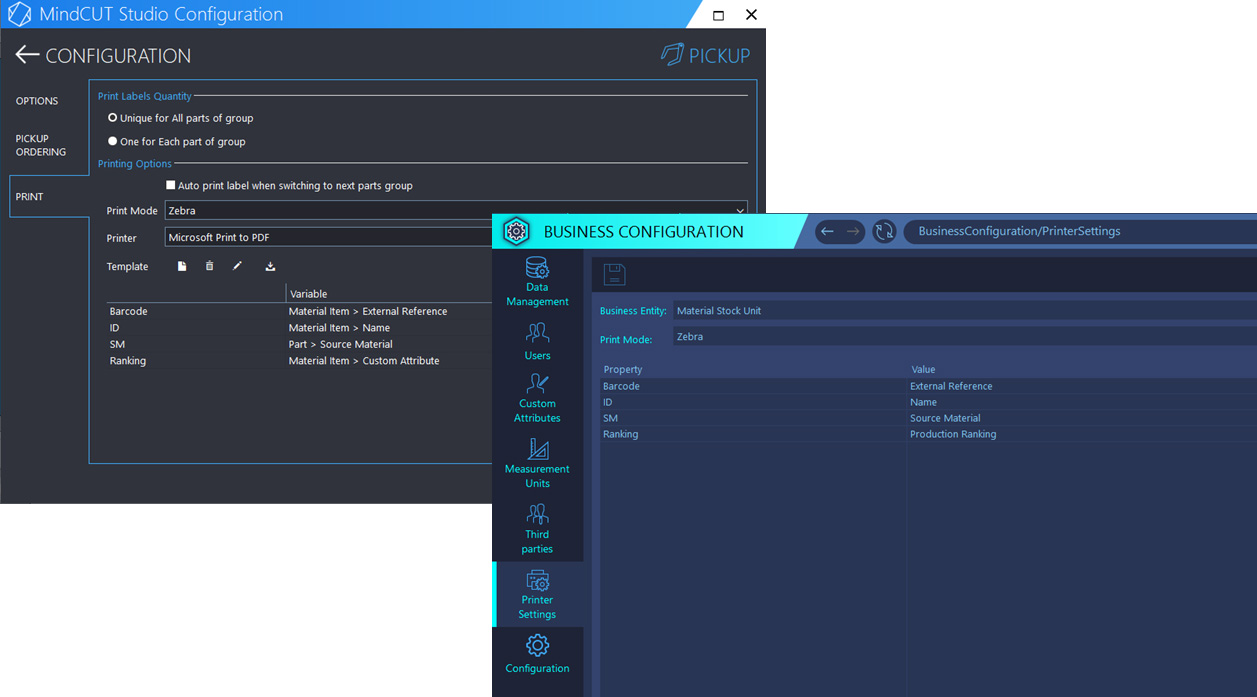

Customizable labels for different entities

Configurable customizable label template to be used differently for each business entity.

Sorted templates

Templates sorted in alphabetical order.

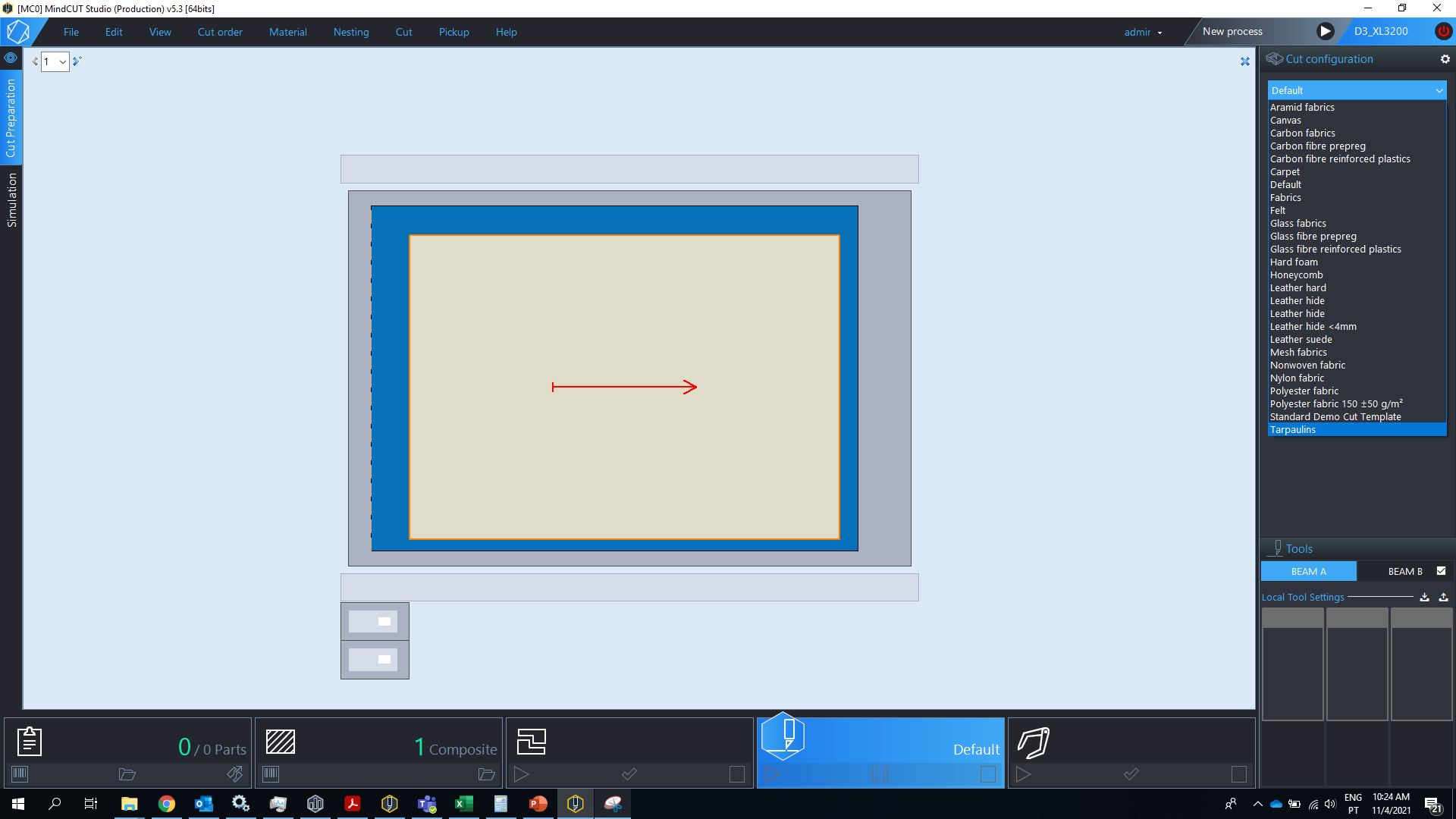

D3 single beam/double beam switch

D3 switch between single beam/double beam under standard permissions.

PDM custom attributes as filters

Custom attributes coming from PDM can be used as filters for interactive nesting.

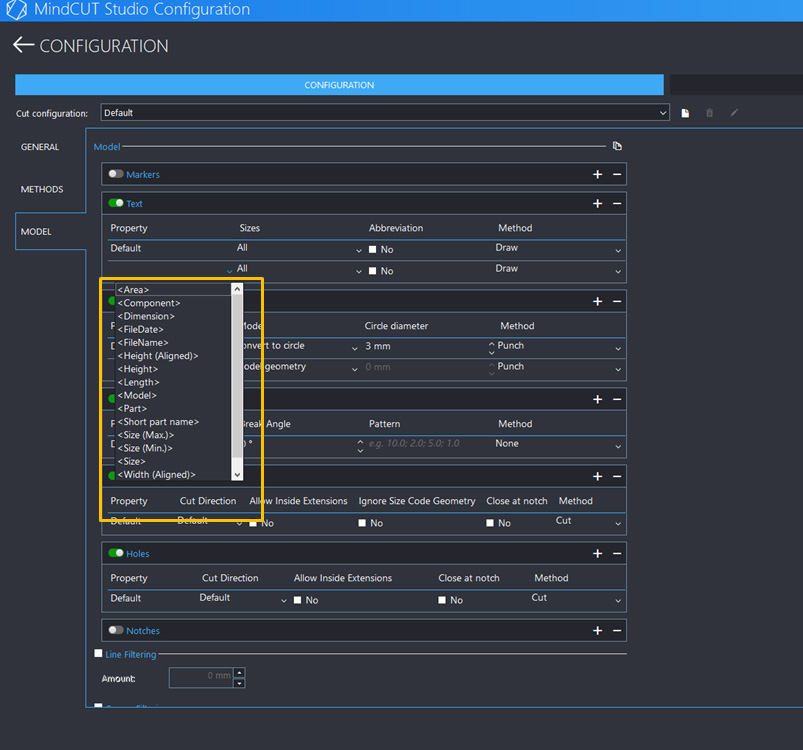

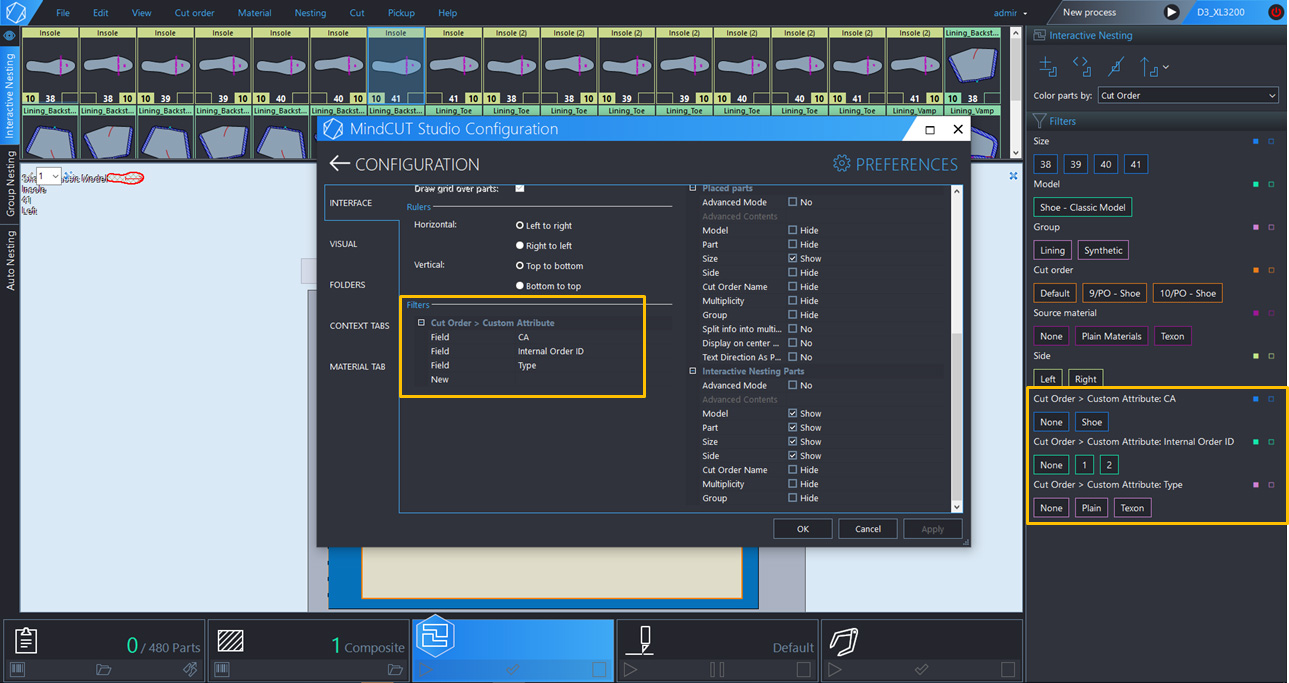

Custom attributes for display and print

Custom attributes can be displayed and printed while picking up parts.

Enhanced symbols engine

Improvements in Symbols engine for a full compliance with Lectra/Humantech marking language.

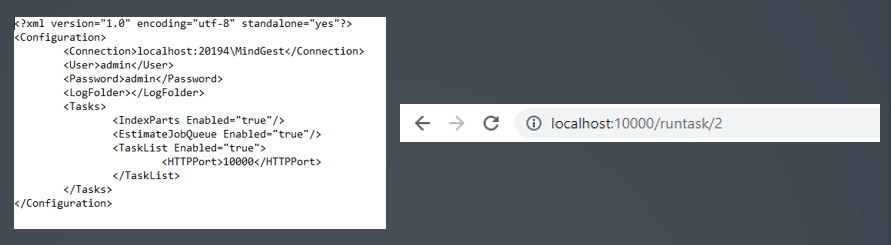

Data Integration Center trigger

Support for external trigger to start Data Integration Center task.

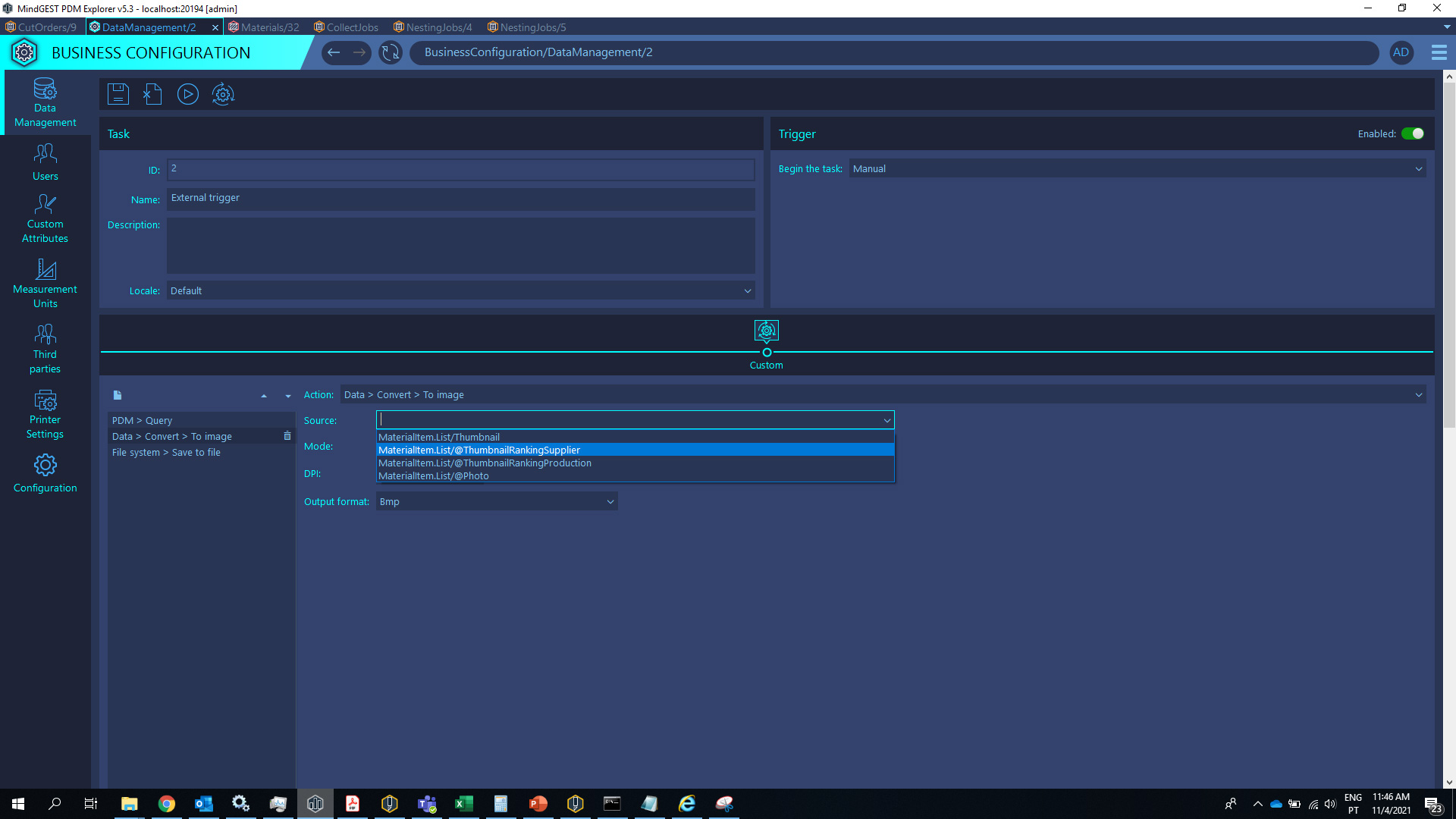

Export elements via Data Integration Center

Possibility to export pictures, thumbnails, and ranking results via Data Integration Center.

CAD labels exposed

Exposure of built in CAD labels in text class.