THE RIGHT SOLUTION FOR TRANSPORTATION & UPHOLSTERY INDUSTRY

MindCUT is an integrated and modular set of solutions for optimization of production processes and automation of cutting systems, suitable Transportation and Upholstery industries.

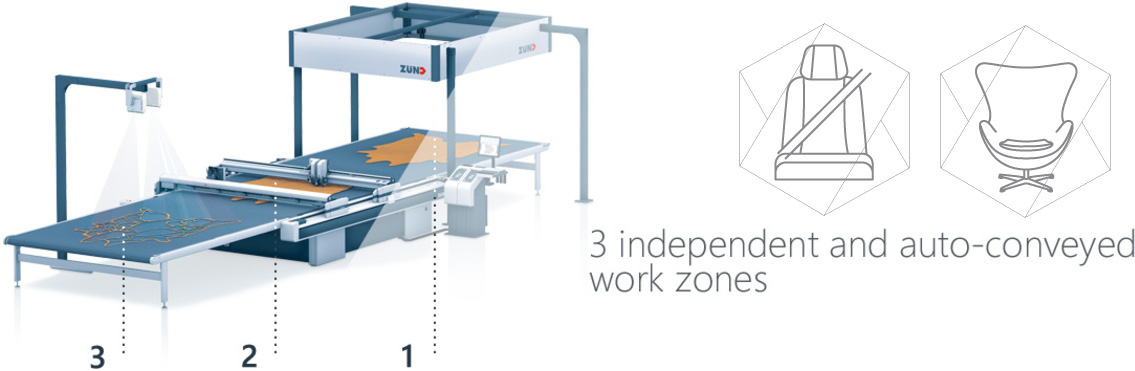

MindCUT Automatic Cutting System for Transportation & Upholstery platform is based on a Zünd G3-2XL3200 cutting machine.

This platform comprises 3 independent and auto-conveyed works zones. The transport of leather hides between work zones is accomplished via an automatic moving system, based on a continuous conveyor.

The 3-stage configuration enables simultaneous, continuous and centrally orchestrated operations on each work zone: