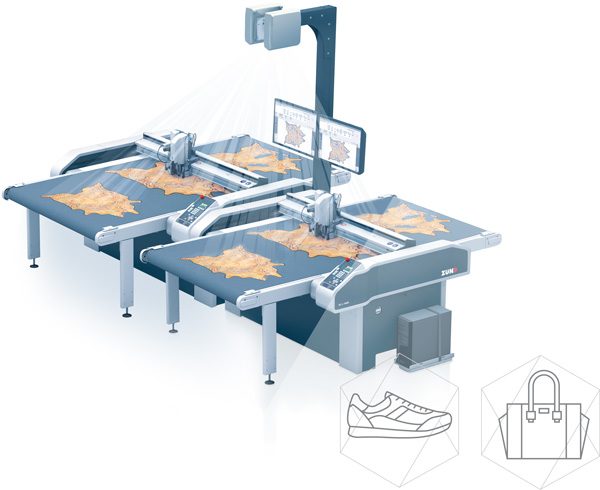

A double head cutting system for flexible production. For demanding medium production volumes, the system adopts an innovative approach: the 3-stage sequence is performed on a dual and parallel production line.

All operations are performed directly on a double machine set, assembled in parallel.

Each machine is a complete, compact, and ergonomic three-stage operation line. A feeder moves the materials from stage to stage.

Diverse materials can be processed in sequence and/ or in parallel, in a continuous and simultaneous operation.

The cutting orders can be flexibly targeted to a machine or into both machines.