Mind Technology

Creative Solutions for Your Industry

Mind Technology

Creative Solutions for Your Industry

Select your language

MindCUT

Cutting automation & control

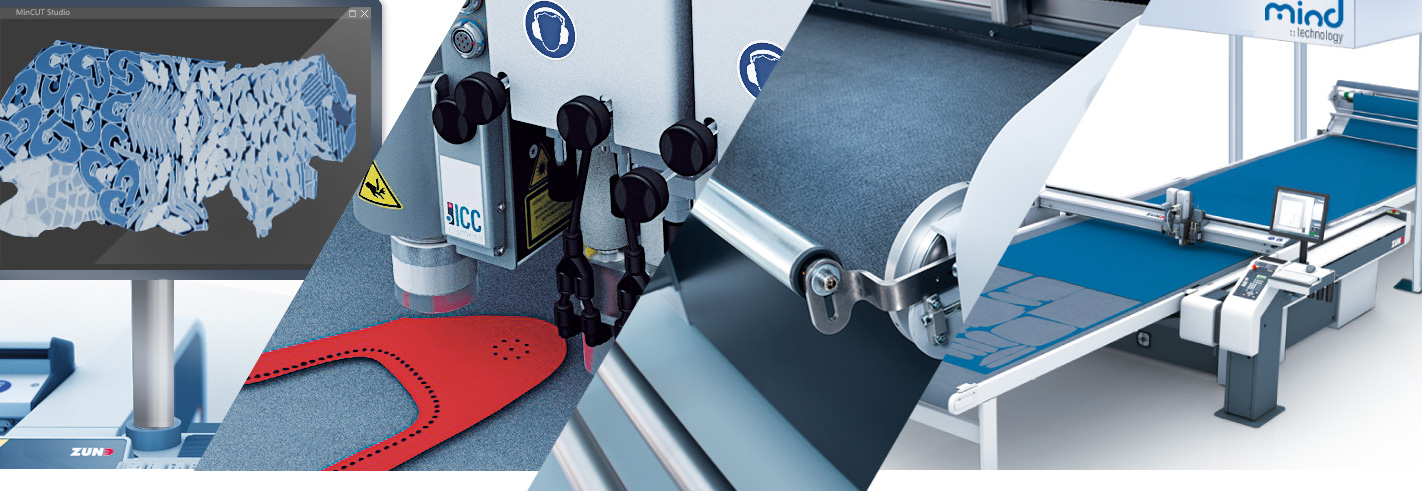

Integrated and complete automated cut cells systems

Mind designs, integrates and implements the best and most complete cutting systems on the market, adding to its expertise and experience in industrial automation software a strong cooperation with equipment manufacturers.

The systems are configured for any production volume and workflow, from small workshops, producing samples or small series, up to factories with medium or large full productions.

The configuration is very flexible, customizable, and includes all the required software and physical components – cutting tables, transportation systems, projection systems and digital cameras – for all the production phases – digitizing, nesting, cutting and picking.

MindCUT Automatic Cut Systems, seamlessly integrated with MindCUT and MindCAD solutions, offers you unbeatable advantages.

Competitive advantages

-

FLEXIBILITY AND PRODUCTIVITY

The combination of the MindCUT software with specialized equipment allows us to offer cutting solutions, flexible and adapted to your specific needs, thus enhancing your productivity.

THE RIGHT SOLUTION FOR EVERY SEGMENT

Streamlined solutions for flexible and efficient production

MindCUT is an integrated and modular set of solutions for optimization of production processes and automation of cutting systems, suitable for Footwear, Leather Goods, Transportation, Upholstery, and Apparel industries.

The solutions delivers a complete and configurable set of tools for automated cutting solutions, including digitizing and classification of materials, online and offline nesting, automatic or interactive nesting and precise cutting control.

HOW DOES IT WORK

Cutting Room operations

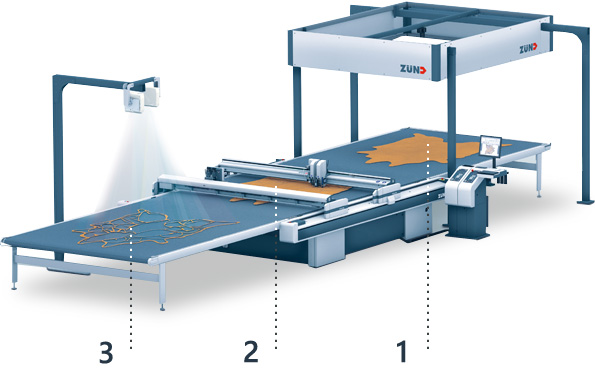

The 3-stage configuration enables simultaneous, continuous and centrally controled operations on each work zone

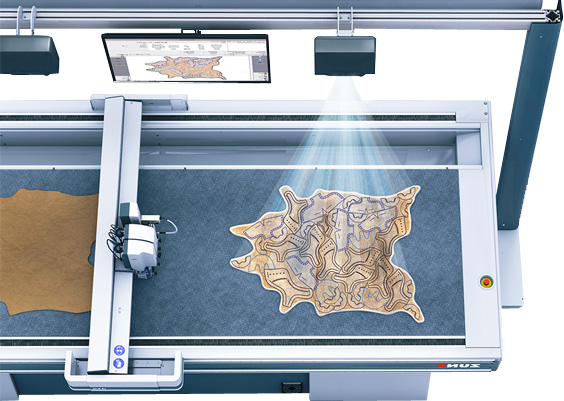

The first work zone – a flat extension table, equipped with a digital camera and a lighting system - where capture and recognition occur, together with automatic nesting and parts` matching.

High precision automatic cutting machine and cutting tools ensure the quality of your finished products. A dynamic vacuum system discards the paper and plastic as consumables, keeping reliability and cut quality.

The pickup is done on the third work zone – a final extension table of the cutting machine, equipped with a projector that highlights the parts to be picked.

A complete view of the solution

Integrated solution for every industry