MindCUT Studio® 2016 release offers the following new features and enhancements:

CAPTURE

Usability and Productivity

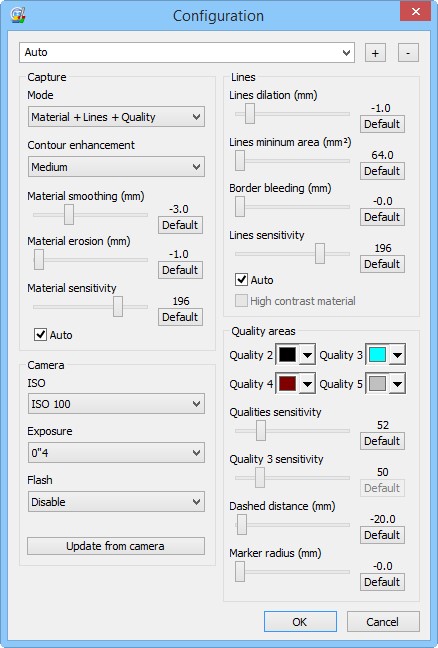

Capture of multiple quality areas

Added support for up to 4 quality areas.

Revised for more cutting topologies options

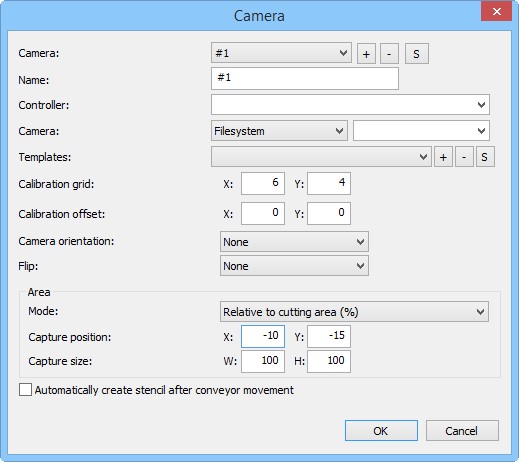

During camera configuration, negative values for capturing are now allowed in capture position.

NESTING

Process Accelerators

Nesting for stripes and plaid materials

Nesting process now supports stripes and plaid materials.

Usability and Productivity

Faster Automatic Nesting

Faster and higher yield for automatic nesting

Nesting validation of part quality areas

Enhanced support for interactive nesting validation of part quality areas.

Offline nesting optimization

Process optimization for offline nesting scenario: when loading a material or nesting from MindGEST PDM for Cutting, the operator is warned if it is already loaded and selects it on the Work area.

CUTTING

Process Accelerators

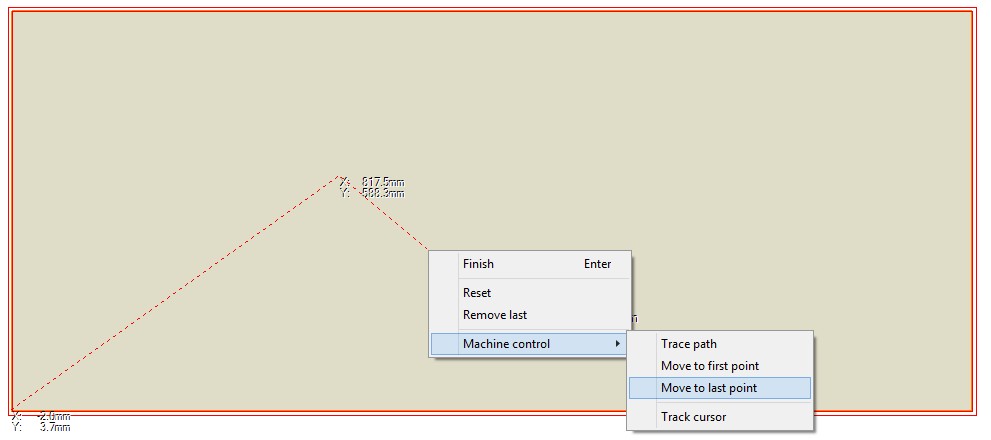

Cutter head positioning

New interactive measurement and cutter head positioning tool.

Cutting sequence ordering

New options to control inner part elements cutting order.

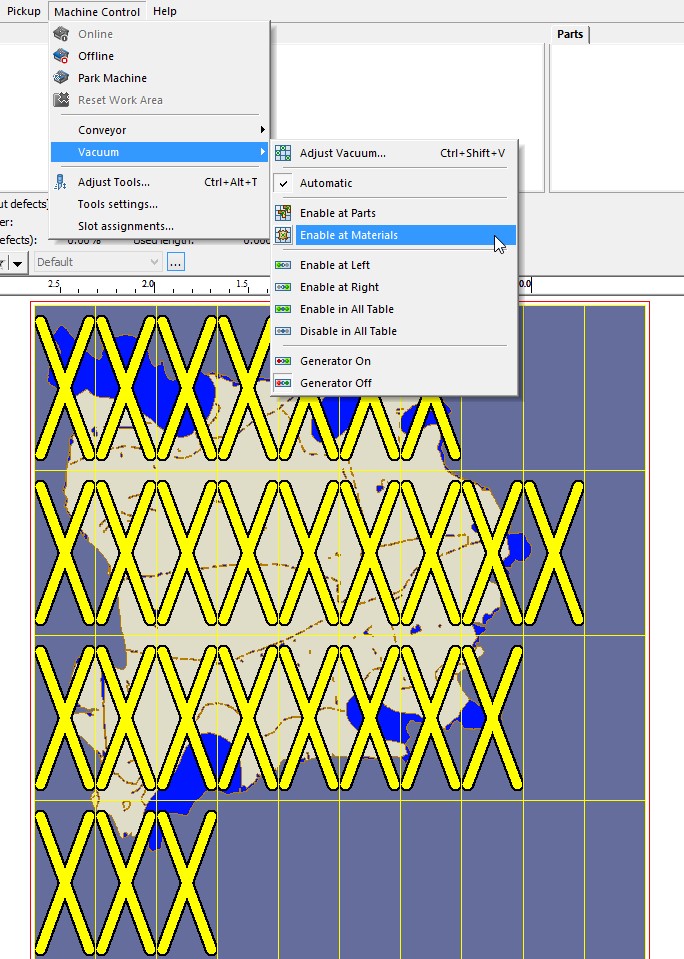

Interactive vacuum control

New options for interactive vacuum tool.

New cutting orientation option

In Preferences – Options you can now define the parts cutting orientation (Clock Wise or Counter Clock Wise).

New visualization grouping option

In the Workarea visualization grouping selector, "Group" was added as a new grouping option.

Optimization options for parts with stencils

In Preferences – Visual you have now an option to show/hide stencils in parts toolbar.

Usability and Productivity

Automatic alignment of material

Automatic alignment of material slices after cutting by reference lines.

Cut configuration interface optimization

Zünd Controller configuration data is now only read when required.

Easier working area navigation

Zoom to Area and Zoom/scroll to arbitrary place on material in the rightward conveyor setting is now supported.

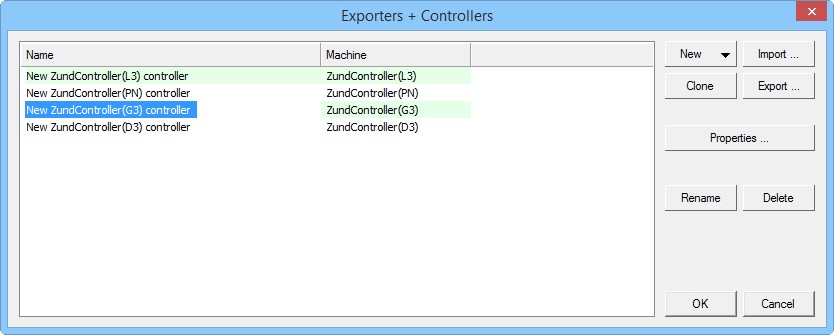

Enhanced Import, Export and Controllers management interface

Importers/Exporters/Controllers management interface was redesigned for coherent usability.

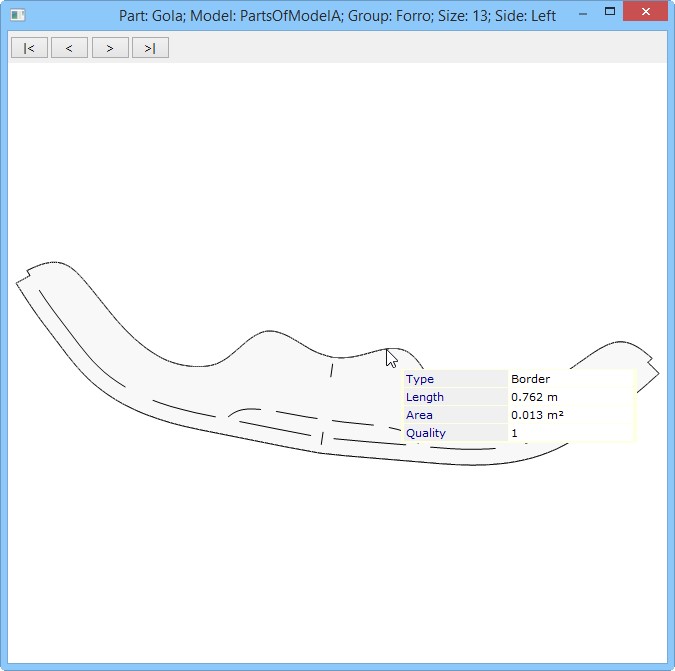

Enhanced Part browser

Extended information on rollover; integrated navigation with parts bar.

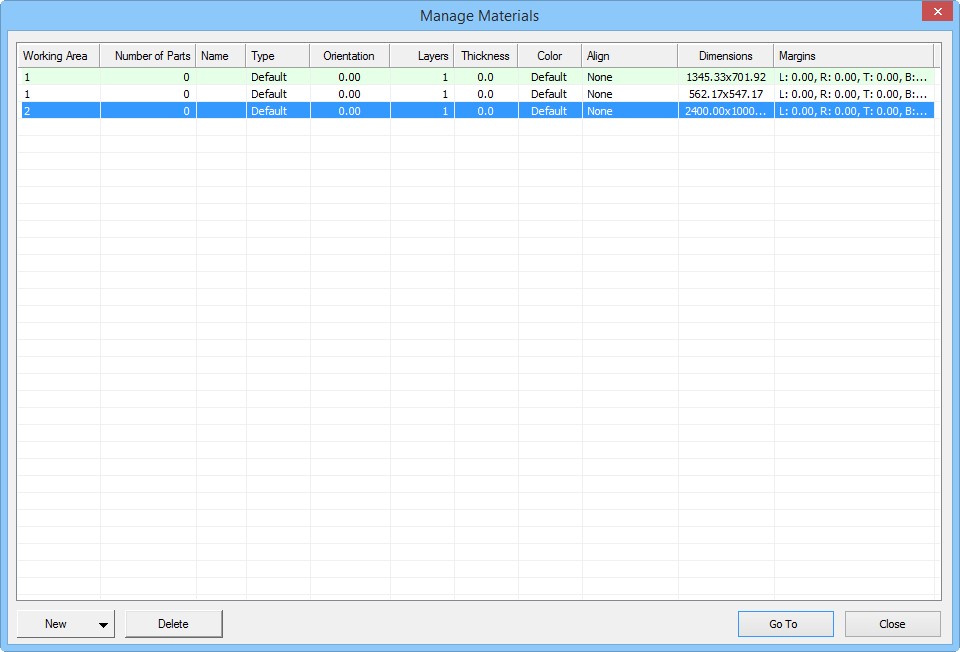

New material management interface

Extended material management for various materials, not restricted to the active work area.

Part label customization

Enhanced support for part label customization: in Preferences – Parts define fields and label configuration for Placed Parts and Parts being Placed.

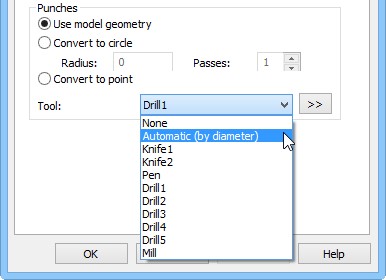

Punch validation

In Machine Setup – Properties – Model (1) there are new options for punch validation before cutting.

New cutting topologies options

In Preferences – Process there are new process options for Prune Rules: By Parts After, By Max Cut Materials and By Max Cut Work Areas.

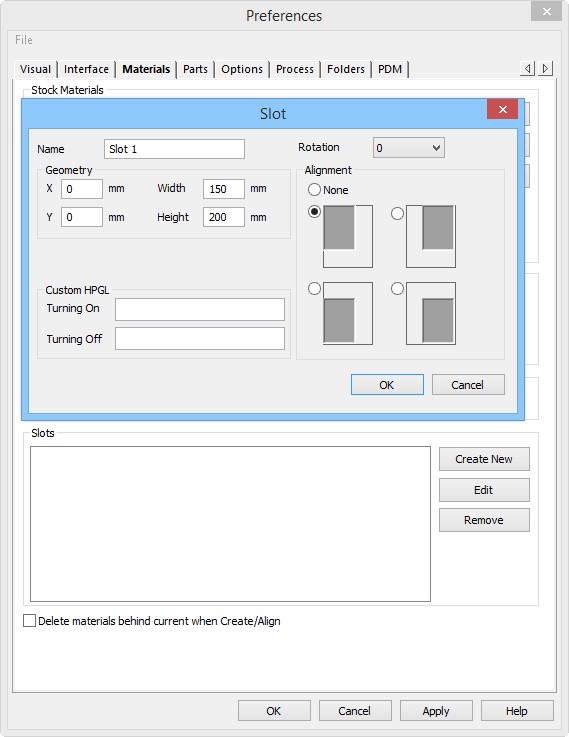

SLOTS FEATURES

Process Accelerators

Slot definition over cutting area

Support for slot definition over cutting area.

Slot custom vacuum options

The HPGL sequence now controls each slot's vacuum control.

Slots nesting batch

Slots configuration now supports nesting batch cut.

Interoperability

Zünd D3 dual-beam support

Support for Zünd D3 dual beam digital cutter control, with a new controller including D3 synchronization on job startup and two-band vacuum control.

Barcode reading

Additional support for barcode reading of business data, for MindCUT Jobs and Projects.

Digital Camera Canon 5DS support

The Canon 5DS digital camera driver is now supported.

HPGL import

New options for HPGL import, keeping original data integrity.