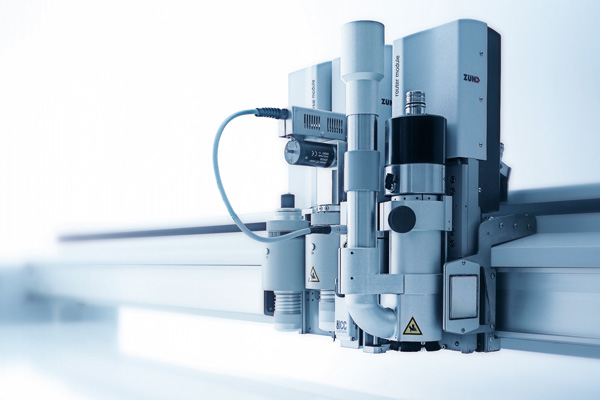

Cutting system for samples and small series production. A compact and ergonomic system with the features of a complete system including digitizing, nesting, cutting, and picking.

All operations are performed directly on a single cutting table – an ergonomic cutting board - in a very flexible and efficient process.

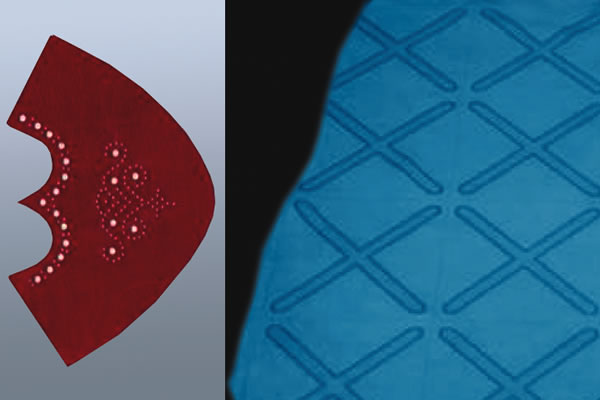

Twofold working areas for continuous or simultaneous operation, enabling the processing of more than one material.

Optional digital cameras and video projectors, directly over each working area.

A dynamic vacuum cell system efficiently fixes the materials, thus delivering high reliability and cut quality.