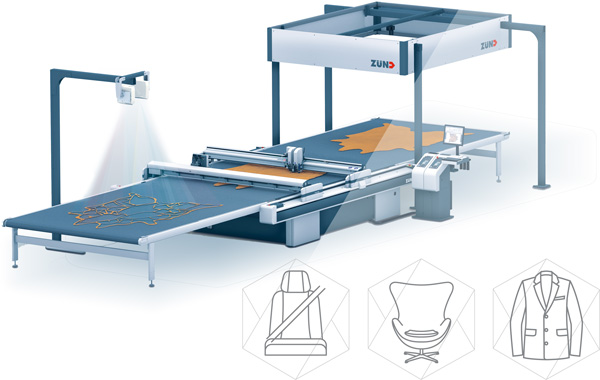

Complete system with 3 independent and auto conveyed work zones for continuous (1) leather capture, recognition and nesting, (2) automatic cutting, and (3) parts pickup.

A flexible 3-stage system that fits any industrial sector and any type of production. In a very competitive world, companies need flexible and reliable solutions to supply the market very quickly, whatever the challenges are and where quality is always a must...

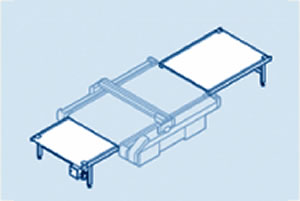

The conveyor solution includes 3 working areas, operating simultaneously and in continuous mode, returning high throughput and cutting quality.

The 3-stage solution includes: capture, recognition and nesting, a cutting area, and finally the picking-up area.

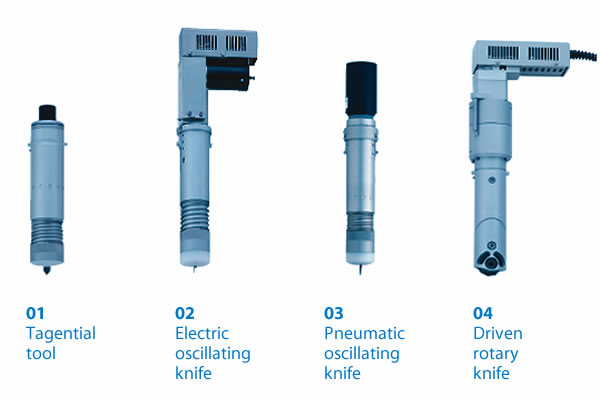

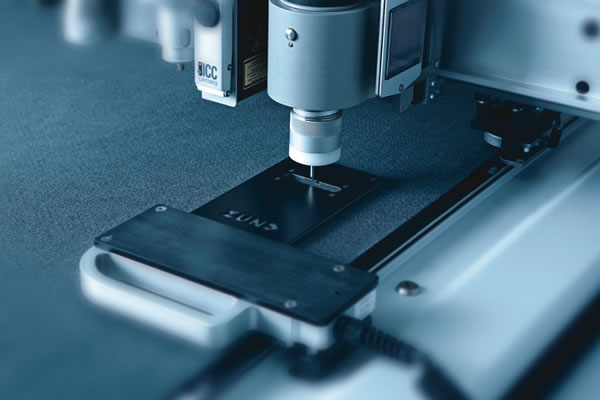

Depending on the materials to be cut, different system configurations are possible, both in terms of hardware and software. The use of digital cameras, video projectors or different software modules depends on the layout that best fits the target market.